Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Off-center hole in rudder blade (Skerry)

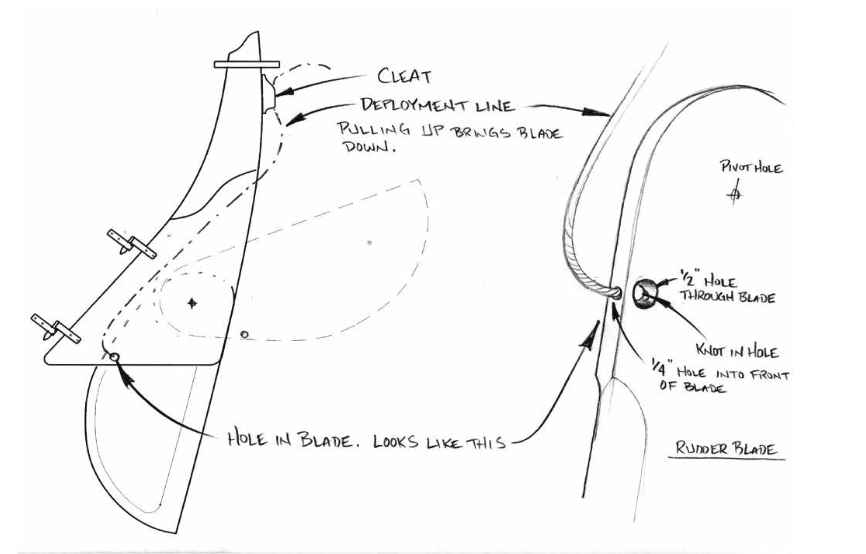

I am building a Skerry, and working on the rudder. There is a 1/2" pre-drilled hole through the blade, in the top of the rudder (I'm building from a kit). I drilled a 1/4" hole through the front of the blade, connecting to the larger hole. Here is a diagram from the Skerry manual.

A line for raising and lowering the rudder goes in through the smaller hole and is knotted inside the larger hole. I managed to drill the 1/4" hole off center. I'm wondering if the thinner edge of the blade is going to be strong enough, or whether I need to refill the hole and try again.

Advice and ideas welcome.

1 reply:

RE: Off-center hole in rudder blade (Skerry)

» Submitted by Mummichog - Thu, 8/3/23 » 11:28 PM

I drilled my skerry rudder blade per directions, pretty well centered and straight. I yanked the blade down a bit harder one time than normal, mostly in a hurry. The knot drove into the hole more than before and split the plies. It didn't pop all the way through, but damaged the plies significantly.

After drying it out, I used some epoxy with a bit of cel-o-fil to glue the plies back together, using a c-clamp and some plastic sheeting to press it back together. After curing, I sanded it down a bit then laminated some scrap fiberglass cloth over the edge to reinforce the plies around the hole. After that cured, filled the weave then redrilled the holes, coating the insides with a bit more epoxy to seal them. Then revarnished the whole thing. You can hardly tell I did the repair. The upshot is that even if the hole is exactly centered, you can still rip out the ply with too hearty a yank. Yours would almost certainly sustain damage sooner or later with the off center hole.

You could fill the off center hole with fillet mix and redrill. Or, you could go the route of reinforcing what you have with some epoxy and fiberglass. If you do that you may have to sand the inside of the cheeks where the hole swings inside to make a bit more room for the thickness of the fiberglass. And of course reseal the surface after sanding.