Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Tool & Materials - Chester Yawl

This winter I will be building a Chester Yawl, my first build and would like to be prepared. I have a variety of basic woodworking tools.

I will definately need more clamps - about how many?

What other tools are essential to the building of a Chester Yawl?

Epoxy containers and spreaders, block plane, scrapers..,

Which tools would "be helpful/useful"?

Many thanks for suggestions!

Dave

21 replies:

RE: Tool & Materials - Chester Yawl

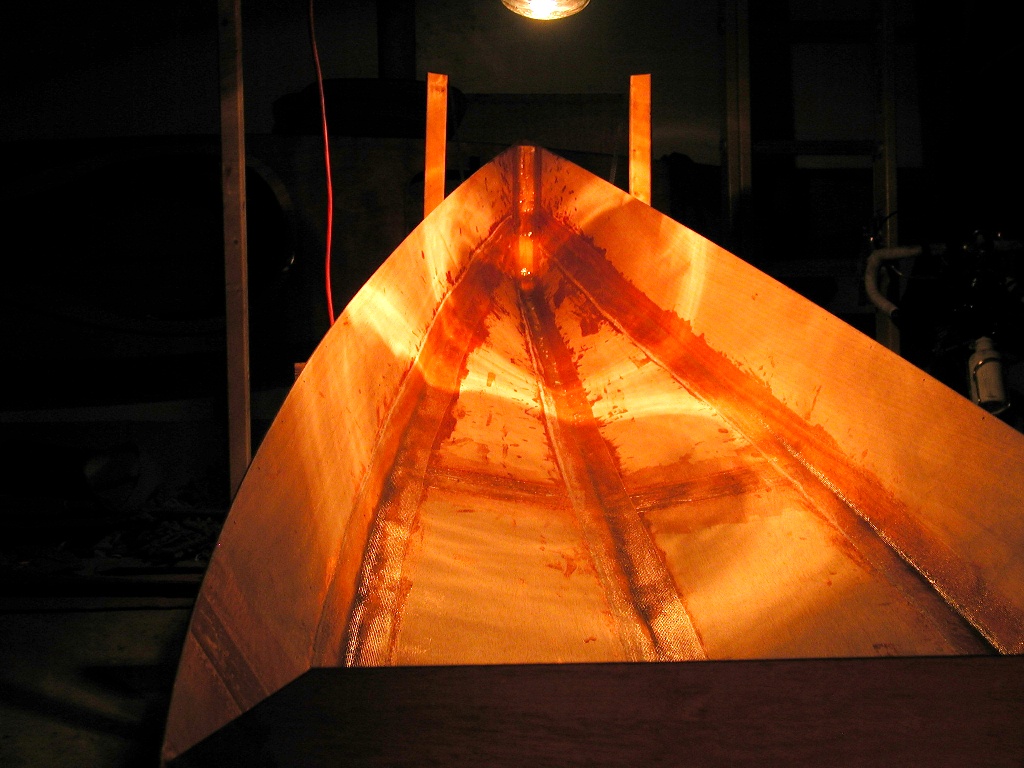

Also, since you're doing a winter build, depending on where you live you may need heat. At the very least, heat lamps.

You may also need a space heater but I can't help you with that. When the heat lamps can't handle things I give up building until Spring.

Laszlo

RE: Tool & Materials - Chester Yawl

Great advice from Laszlo! I will add somethings I found useful.

First is a high output soldering iron. Maybe I was just messy in some cases, but I often had copper stitches stuck in place with epoxy. Through other posts here I learned that I could easily and cleanly remove the stuck stitch by warming it as I pulled.

I also used strap clamps a couple of times to bring the planks tight to the frames.

A word of warning: I bought my kit this Summer and it came with the instructions for the old pre-puzzle joint kit. It won't work as written! Since the frames stick through the hull you will epoxy them in place when you glass the garboards and then won't be able to remove them to glass the hull interior. It was hard for me to see all the cascading implications but I think I came up with a working solution by glassing the interior sections each individually, filleting the frames and bulkheads, and then glassing the keel and garboards. (I am not currently home but in a week or so I could send you more info from my notes if you like, message me if you would. Better yet, I would like to see CLC provide updated instructions.)

RE: Tool & Materials - Chester Yawl

���Plus a heat gun to soften epoxy globs and mistakes (don't scorch the wood), a bbq starter to heat and remove wires, an orbital sander and a mask and maybe a wood burning kit to add some personal art and at least your name to your masterpiece.

RE: Tool & Materials - Chester Yawl

Thank you for your replies (and keep them coming if there is more to add).

I do live in NH, so temps in the winter may be a challenge. Our basement will soon be better insulated, which should warm things up some but I will put a thermometer down there and will need to time my work based on the temps.

Have any of you used the "split PVC pipe" suggestions under Tips instead of clamps? If so, have you found them to be reasonable substitutes, or not?

Many thanks!

Dave

RE: Tool & Materials - Chester Yawl

I made up some of the PVC clamps from some leftover pipe. They work, but in my experience, only are useful for certain specific clamping situations. I find the commercial clamps more versatile. You can find spring clamps in bulk quantities if you look around, either in the big box stores or online. I also have a few of the ratchet clamps both large and small and a couple of deep throated sliding bar clamps that are sometimes just the ticket to reach something. I don't have a permanent workbench so I use the deep throat clamps to hold down pieces on my temporary bench, a piece of 3/4" ply sitting on my spare sawhorses.

I am no expert with a plane, but I do have a couple of Stanley block planes and a wood bodied rabbet plane. I read up on "scary sharp" honing techiques online and it works. I bought some of the mylar film honing abrasives from McMaster-Carr online and glued them onto some scrap plate I had. I found a Stanley sharpening jig at Lowes. A decently sharp plane is a revelation for chamfering, beveling, smoothing and tapering both solid stock and plywood without generating all that sanding dust. Easier to clean up the shavings than dust. I didn't use a router (don't own one) and just used the planes to round off all the corners on my rails and spars. Put 3 bevels along each corner of rail or spar stock, then hit it with a little 80 grit to smooth the last edges and you don't need that roundover bit in a screaming router.

RE: Tool & Materials - Chester Yawl

Dave,

I gave those a pass. They sound easy to make, but the heat of the sawblade melts the PVC a little. You end up with PVC dust literally welded to the clamp (as well as all over the shop) and that has to be cleaned off. The edges of the clamp can act as a plastic chisel and mar the wood, so those need to be rounded. Doing all the cleaning and rounding and cleaning again would get very old very quickly.

The thickness of what you can clamp is also limited with the PVC clamps, and if you use them long enough they will fail through fatigue cracking.

If you keep an eye out at the big box DIY stores, you can often find spring clamps on sale as a loss leader and grab a bunch. I've paid as little as 50 cents for a real spring clamp. Between the my time, the nuisance value and the fact that PVC pipe isn't free, either, I prowl the sales.

Laszlo

PS - just took a look and saw that Home Depot has 3/4" capacity spring clamps fo 47 cents each, 2" capacity for 99 cents. 4" PVC pipe is $21.50, or the same as 21 to 45 spring clamps (depending on the size you buy). Then there's still the labor of cutting, rounding and cleaning. Life's too short.

RE: Tool & Materials - Chester Yawl

Hard to believe we missed it, but you will also need a flush-cut saw when working the stern. And be careful when using it, most will only cut flush on one side without making a mess.

RE: Tool & Materials - Chester Yawl

Oh, clean and save your empty yogurt containers, plastic Chinese takeout containers, etc. That way you always have disposable mixing containers of all sizes for epoxy, and paint and varnish tubs, esp. for small jobs. Also recycle some of those free chopsticks into various tools for poking, smoothing, and general probing.

I also recycled some empty gallon paint cans by filling them with gravel to be weights for clamping epoxy joints.

And while I always have some foam brushes around, I'm getting used to using a proper pure bristle brush for varnish. Clean it in odorless mineral spirits, particularly if you're in the basement. You'll smell turpentine through the house if you use that. I still use rollers and foam brushes for paint though.

RE: Tool & Materials - Chester Yawl

Paper towels, disposable latex gloves, sandpaper (did nobody mention sandpaper? Get more!), polythene sheet, acetone or other stuff for cleaning up . . .

RE: Tool & Materials - Chester Yawl

I wish we'd had these "riffler" rasps:

http://www.clcboats.com/shop/products/boat-building-supplies-epoxy-fiberglass-plywood/riffler-rasp-set.html

...when we built our Passagemaker Dinghy. If they are any account (which I have no reason to doubt--all the other tools we bought from CLC were superb), they would save a lot of trouble cleaning up irregularities in the fillets and other "inside" angle joints. I spent many a frustrating hour working with sandpaper held over rounded off dowel of various sizes and other odd bits of wood trying to work out stuff I missed with the "alcohol wetted gloved finger" smoothing trick. If we ever build another boat, these rasps are definitely on my list of additional tools to have.

.....Michael

RE: Tool & Materials - Chester Yawl

Many thanks!

These appear to be very good ideas, many low-tech. I may; however, take advantage of the current clc sale and order a few specific items.

Dave

RE: Tool & Materials - Chester Yawl

Dave, Where in NH? I've got a bunch of spring clamps from a Shearwater build- you're welcome to borrow them for your build. JN

RE: Tool & Materials - Chester Yawl

Going back to your tool wish list, when I built my Chester Yawl I was impressed with how few tools were really necessary. Several that I bought were used very little.

Even though the manual shows a random orbit sander being used to sand the hull, I found mine more or less useless. The narrow planks make it likely that a machine sander would cut too deep on the exterior laps and it wouldn’t fit the concave interior at all. Hand sanding is the way to go and, although the initial expense seems high, I find the rolls of self adhesive sandpaper and the foam sanding block that CLC sells makes hand sanding productive and almost enjoyable.

There are many fillets in the Chester Yawl so you learn to make tidy ones as you go. Using the disposable pastry bags rather than the standard freezer bags the manual recommended would help speed that learning curve. They fit into corners and allow you to see what you’re doing much better.

At the sanding and finishing stages good lighting becomes important. A bright floor lamp that can be moved around can make up for the dimly lit spaces most of us work in.

Oh, if you glue the rub rails on one at a time you can get by with half as many clamps.

enjoy your build, it’s a beautiful boat,

Cameron

RE: Tool & Materials - Chester Yawl

Don't go nuts with tools ,you don't need much.that being said you'll find other uses for them .my list: pull saw , 4 in hand rasp, belt sander, shop vac, drill, good pair of sissors ,clamps, ,might need a jig saw if you've got to cut out the seat patterns, I'm on boat 5 and I find myself using the random orbital sander less and less.I spray sheets of sand paper with spray adhesive fold it over and cut 5" strips of now double sided sand paper and hand sand. The only thing I like the ros for is finishing work. But I do love my belt sander for shaping wood.

RE: Tool & Materials - Chester Yawl

Dave- right down the road in Wolfeboro. I can bring up whenever you would like.

RE: Tool & Materials - Chester Yawl

One important bit of equipment that is often (pardon the pun) overlooked is safety glasses. I have trouble with the goggles foging up so I got six or seven pair with the eyebrow and temple pieces. I got so many because they seem to accumulate in the house or somewhere other than where you need them.

RE: Tool & Materials - Chester Yawl

Thanks again for comments - including suggestions of the ways in which tools were utilized and notes on what was truly used and what got limited use. Also thanks for the words of encouragement on the build and the boat. Am looking forward to it!

Dave

RE: Tool & Materials - Chester Yawl

When you get to the stage where you will be needing the clamps or other tools, send me an e-mail and we can get together. [email protected]

Joel

RE: Tool & Materials - Chester Yawl

Be careful gluing the rubrails one at a time. On some boat designs that works fine, on others it will pull the side without the rubrail into an undesired shape and you end up with an unfair sheer an/or an asymmetric hull.

Laszlo

RE: Tool & Materials - Chester Yawl

» Submitted by Laszlo - Sat, 11/25/17 » 9:22 AM

1. Clamps - more than you could ever imagine. They should be showing up in your house and shop like paperclips in an office. On a bit more useful note, I end up usually needing two for every for every foot of the boat's length, plus 1/2 dozen for luck.

2. Never built a Chester Yawl, but I found my razor saws, Shinto rasp, bonsai saw, carpenter's square. level, sanding block, block plane, twist drill and bits, screwdrivers, vise grips, combination pliers, diagonal wire cutters, needle-nose pliers, small hammer, cabinet scrapers, wooden mallet, razor knife, razor blades, pencils, orbital sander and shop vac useful for all boat builds. When building from scratch instead of a kit, I also use a jigsaw. Note the almost total lack of power tools needed. The one time I had to pour lead for a keel, an electric crucible was useful, but the CY doesn't need that.

3. Dedicated scissors for cutting glass, as well as the stuff you mentioned. Plastic putty knives that you can trim to shape for filleting. Lots of yogurt containers and popsicle sticks. Syringes (with and without needles, assuming you can get them without being hassled by a government that always thinks the worst of its citizens).

That's all I can think of. Have fun,

Laszlo