Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

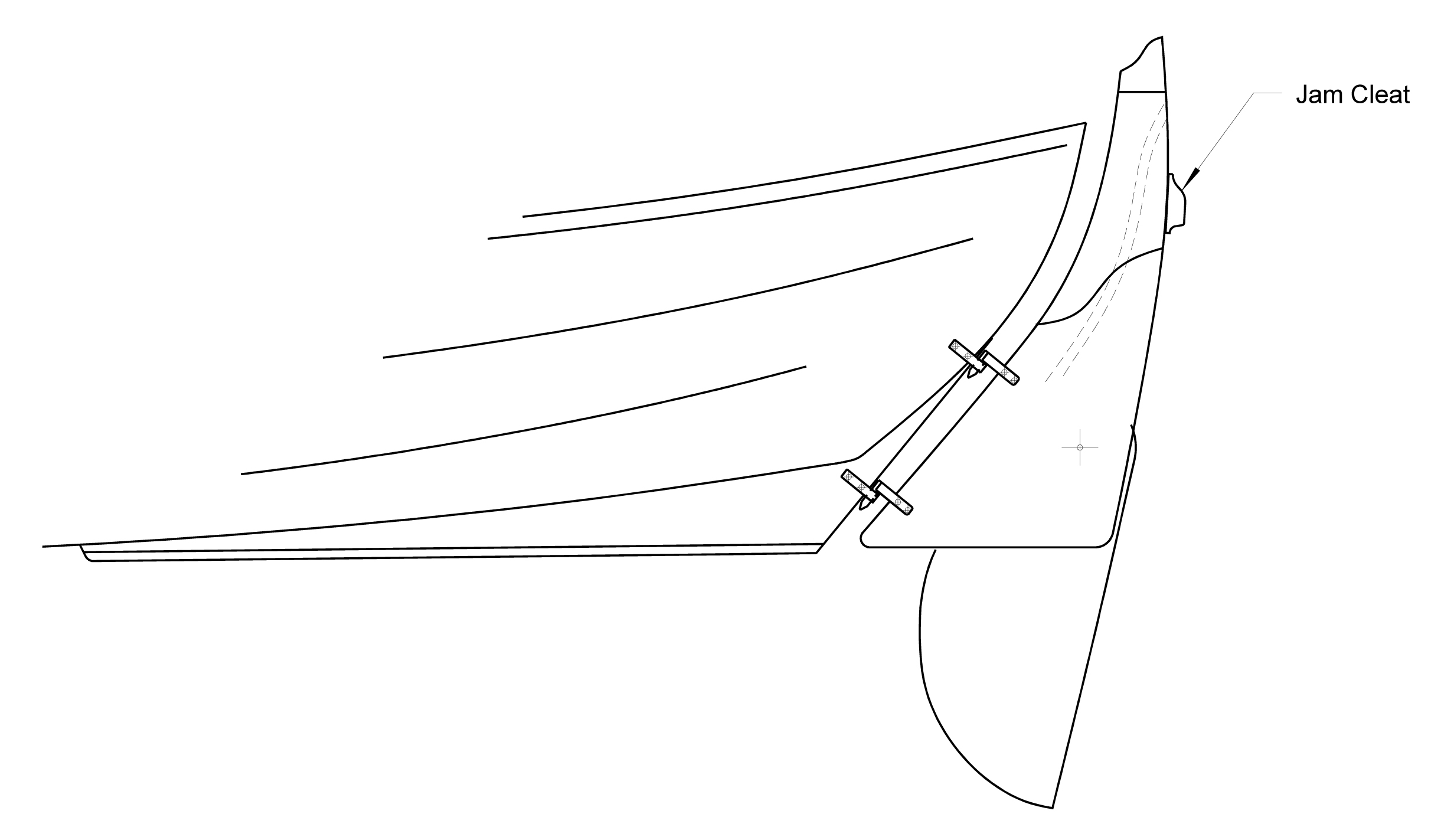

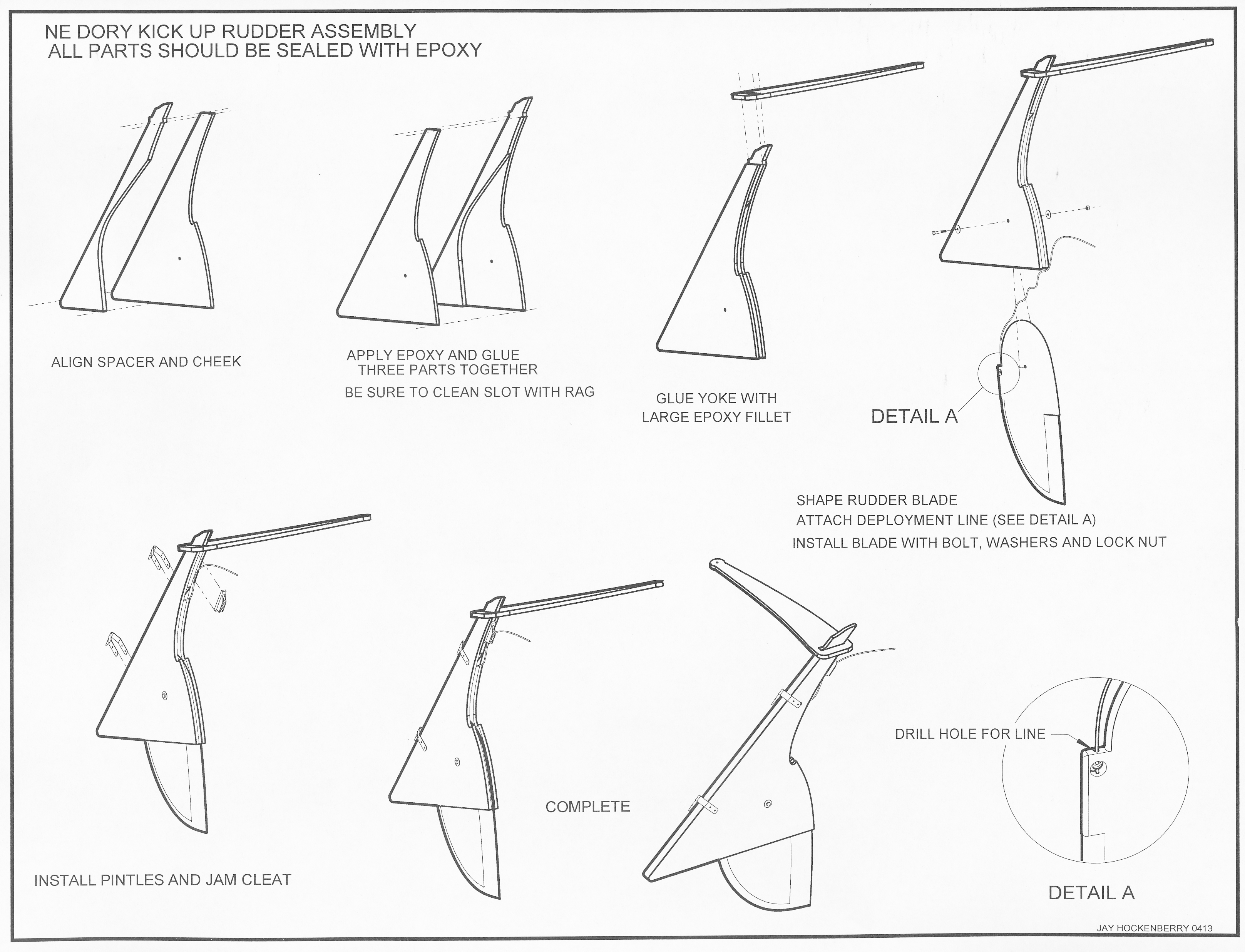

The rudder components in my kit, when assembled and glued up have the rudder blade deployment line exiting only 1 7/8 inches below the ledge at the top of the cheeks where the yoke sits.(see sketch of parts, pg. 110 of builder's manual). No room to place a jam cleat .

The exit point in the parts sketch on pg. 126 show the line exiting the rudder housing several inches lower. I can't figure out how it came out there, or what the correct fix for this problem would be.

7 replies:

RE: Skerry rudder problem

doc,

same thing happened to me - I simply drilled a hole through the yoke and installed a small jam cleat above the yoke rather than below as the instructions show.

Mihai

RE: Skerry rudder problem

Thanks Mihai. I was thinking of doing the same thing. I had an email from John Harris who said he had tried several things, including placing the jam cleat under the port where the blade deploy line exits.

RE: Skerry rudder problem

My reply to Joe:

"I've tried the cleat in at least three different places; above the

control line exit port (on earlier versions), on the underside of the

yoke (as awkward as it sounds), and below the exit port. The latter

(see below) turns out to have the best ergonomics when you reach

over the stern of the boat to deploy the rudder.

My colleague Bill has a Skerry he built for his own use, with the most

novel approach of all for the deployment line: no cleat at all. He

chose a bit of line that was a fairly tight fit in the internal

channel. The friction of the line in the channel is enough to keep

the blade from floating up unless he hits something."

John--? RE: Skerry rudder problem

Hey John,

It seems like you told me the Skerry kick up rudder is the same as the Dory kick up rudder kit you sold me? If so, I assume the clever way for the downhaul on the rudder you describe above would work for me too?

Had you ever envisoned a turning block on the side of the rudder to this line and lay a loose line down so that you could pull the rudder down as you sail away from shore without going aft?

Also does the kick up rudder have an uphaul? Same idea I would think could be used with a turning block on the other side of the rudder for an uphaul line so as to pull it up from the cockpit while beaching so the rudder doesnt drag in the sand/muck.

New question...what about a bungee to act as a spring loaded downhaul and just use one line, an uphaul, which when released would allow the rudder to spring down by bungee tension? I saw this method on boats at the Wooden Boat anniversary show in Brooklin last summer and the owners said that method has proven very reliable and simple. You could still do a turning cheek block on the side of the rudder to be able to reach an uphaul line without going aft so you can pop it once in deep water or pull it when beaching...your thoughts?

Thanks! Curt

RE: Skerry rudder problem

The Northeaster Dory's optional kick-up rudder has a downhaul similar to the Skerry's.

These things can get tricky fast; witness the Skerry's rudder, with just a downhaul.

A lot of production dinghies have some variation of uphaul and downhaul lines for the blades. Maybe half of them work well. The ones that do work, and that look elegant instead of kludgy, tend to be complex.

These days, when something like the Petrel SG's retractable skeg system requires a 43-page instruction manual appendix, I'm disinclined to try to devise such systems for kit boats.

RE: Skerry rudder problem

Chums,

I had issues with my rudder on my first outing with my new boat, mainly due to a "helpful" boat club member telling me what to do and making a mess of things by jamming my rudder down before I was in deep enough water. We draggd along the bottom and scraped the paintwork.

I have come up with a solution which involves a lenght of 5mm bungee attched to the rudder and up through the channel and down to a jam cleat. The rudder is therefore springloaded and will shift up if it hits an obstruction and then ping back down again when it can. The bugee can be tightened if we are swooshing along at top speed.

The for coming ashore, I can simply un clip the bungee and pull the rudder up using a piece of 4mm line attachd to a shackle 6 inches below the pivot point on the top of the blade. This line is then run up through another jam cleat on the top of the rudder stock and holds the drop rudder up to prevent it grounding.

All works a treat. See below:

RE: Skerry rudder problem

» Submitted by doc - Sat, 1/17/15 » 9:17 AM

Correction:

I meant to say that the line exits just 1 7/8 inches below the ledge formed by the TOP DOUBLERS, not the CHEEKS.