Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Fixing centerboard trunk problems

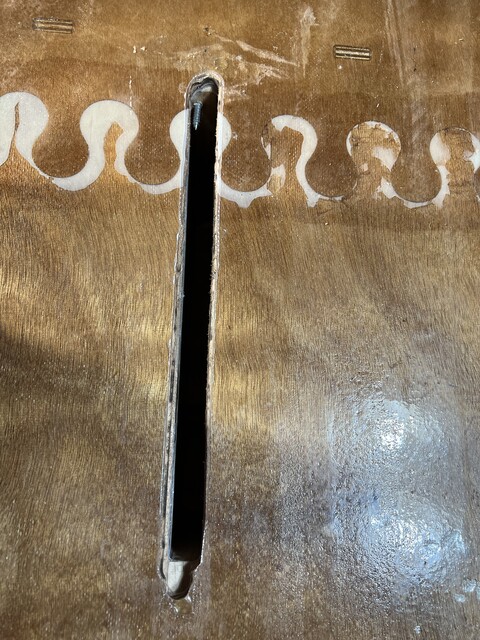

I am working on a Skerry, and I've just installed the centerboard trunk, and cut the slot for the centerboard in the bottom panel. As you can see, there are two problems.

1) I mismeasured, and cut the slot too long. On the left of the photo, at the end of the slow, you can see the spacer of the centerboard trunk.

2) At the other end, I used a too-long screw through the frame into the spacer, and it pokes through into the centerboard slot.

What is the recommended way to fill in the slot on the left?

On the right, I'm going to try to remove that screw. Any advice welcome -- I may be back to ask about how to proceed if the screw refuses to budge, due to all the epoxy involved.

10 replies:

RE: Fixing centerboard trunk problems

The screw problem is more difficult that I originally indicated, because the screw is stripped. I've watched the youtube videos on dealing with stripped screws, but none of them address the problem that the screw is held in place super-tight with epoxy. So, heat it up and then use a screw extractor of some kind? Dig out the wood around the screw and try to loosen it with a vise grip?

RE: Fixing centerboard trunk problems

Definitely heat and extract. Sounds like you're gonna need a partner in crime to hold the soldering iron against the screw in the slot while you run the extractor in the boat.

If that doesn't work, is there any way to get a vise grip or equivalent onto the screw from the slot and drive it out that way?

If not that, have you considered cutting off the protruding part, drilling in a bit and just filling the hole with epoxy/woodflor putty?

That's all I can think of at the moment.

Laszlo

RE: Fixing centerboard trunk problems

I wouldn't mind cutting off the screw, but it pokes into the trunk, as shown in the photo. No room to maneuver, or accommodate tools.

I think I'll try removing some of the wood around the screw and using a vise grip next.

RE: Fixing centerboard trunk problems

Is the head of that offending screw exposed inside the cockpit?

If so you may be able to loosen it from the grip of epoxy by heating with a soldering gun, then drive it out with a large nail set & smallish hammer. Once removed then drive in a bit of solid wood whittled into a taper after you spread unthickened epoxy inside the hole left behind.

Otherwise there may be enough room in the trunk to use a hacksaw blade to cut away the protrusion. Use a vice grip to hold the blade, or wrap several turns of tape on one end for a makeshift handle to protect your skin.

What's with all the whitish areas surrounding the puzzle joint's tabs at the back of the trunk?

RE: Fixing centerboard trunk problems

Thanks spclark. The head of the screw is flush with the frame.

When I next work on the boat, I will try using a triangular taper file to cut off the end of the screw. If that doesn't work, I will remove some wood around the head and try a vise grip.

The whitish areas come from my incompetent epoxying of the puzzle joints. (That was the very first thing I epoxied. I went too quickly from experimentation to working on the puzzle joints.) It's a nice decoration (kidding) around the middle of my boat. I mixed too much epoxy, it started hardening, I kept going, and I also managed to misalign the panels in one case. Lots of sanding later, that's what remains.

RE: Fixing centerboard trunk problems

Problem solved! Thanks again for all the ideas. I tried an idea closest to what spclark suggested. Instead of a hacksaw, I used a thin, tapered file, and cut off the protruding part of the screw pretty easily. The file was also useful for filing down the remaining nub of the screw. I'm going to cover everything (including the slot) with epoxy, and move on to seat installation.

RE: Fixing centerboard trunk problems

Congratulations. Just be sure that you seal it really well, maybe even with a fiberglass patch to prevent microcracks that would allow water intrusion.

Laszlo

RE: Fixing centerboard trunk problems

Laszlo: Thank you, do you mean, a little fiberglass patch over the nub of the screw? I was planning to cover the area with a few coats of epoxy but hadn't thought of a fiberglass patch.

RE: Fixing centerboard trunk problems

Yes, exactly that. The wood and metal have different coefficients of thermal expansion and will expand and contract at different rates. Eventually microcracks will form in the epoxy. The glass patch will have greater tensile strength than the epoxy alone and will resist the tendency for cracks to form. It will also provide greater protection against the board possibly rubbing against the nib.

Laszlo

RE: Fixing centerboard trunk problems

» Submitted by Laszlo - Thu, 6/8/23 » 6:11 PM

Both minor problems. For the one on the left, just fill it with epoxy/woodflour putty. If you're feeling extra paranoid, put a patch of glass over it.

Tight screws in epoxy loosen up with heat, so you can just apply a heavy wattage soldering iron or something similar. Plug the hole with a dowel dipped in epoxy or inject epoxy/woodflour putty into the hole.

Laszlo