Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

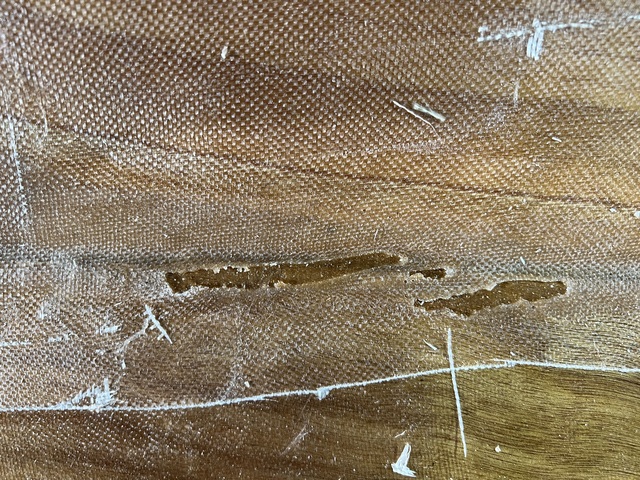

I did a pretty messy interior glass job on my Skerry. In a recent discussion, there was advice about how to apply patches. Laszlo (I think) said that replacing a whole section of glass might be simpler.

I have both problems. My plan is to fix some blisters, and also to replace one section of glass.

So today I removed the bad section of glass. How do I prepare the surface for reglassing? There is epoxy showing the pattern of the removed glass. And there are spots (that were under blisters) that have less epoxy and do not have that pattern. So what do I do, sand away the epoxy?

4 replies:

RE: Redoing fiberglass

This is more than a patch, I've removed the glass from all of one panel (between frames) and part of another.

Let me make sure I understand:

1. Sand off epoxy remaining where I removed the glass.

2. Wet the area with epoxy.

3. Apply new glass

4. Apply epoxy with foam roller

5. Sand and apply final coat

Is that right? I want to verify that I apply epoxy both before and after the new glass (steps 1 and 3).

RE: Redoing fiberglass

1. Best - sand all the way down to wood, but avoid sanding the wood as much as possible to preserve the outer ply. Good enough - sand the textured epoxy flat and smooth. Good enough will be less work, but heavier, than best. The more you sand, the lighter.

2. I'd skip this step and just lay the glass down the same way I'd do it for a new piece of wood. Even if I'd sanded all the way down to the wood in step 1 the pores in the wood will still be filled with epoxy. Adding more will not accomplish anything beyond adding weight and possibly floating the glass.

3. Yep. Apply dry glass and wet it out just as if this was the first time you were putting glass there.

4 & 5 - Fill the weave as normal, whatever tools and techniques you prefer.

Laszlo

RE: Redoing fiberglass

Thanks, I think I can proceed now.

(By the way, before I put down the glass the first time, I applied a thin layer of epoxy, a "skim coat", based on a response to a previous question I had: https://www.clcboats.com/forum/clcforum/thread/51532.html)

RE: Redoing fiberglass

» Submitted by shiloh - Thu, 8/4/22 » 10:32 AM

Sand it all down to make it smooth so theres nothing to snag the new glass, wet it out working from the center towards all edges as evenly as possible, you should be able to do this before your mixes start to set. Removing excess epoxy as you go leaving the weave evanly wet with no dry spots or bubbles or excess pools. Your first weave fill can be applied(i use a foam roller) before fully cured. After that sand and apply aditional fill and final coats. Follow mixing instructions and proceed with confidence.

I should mention that the glass will become clear when wetted out, if it looks white its too dry, if left that way once cured it will remain white, that area will need to be removed and patched.

If its just a repair patch, sand, wet out patch area, apply patch, wet out patch working from center to edges working epoxy in, making sure there`s no dry spots or bubbles, If too much epoxy the patch will float, let cure, sand smooth, feathering the edges, re-wet sand, feather, repeat untill desired finish is acquired.

Patching can be very forgiving and nearly invisible, if done correctly.