Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Trying to finish up sanding of exterior, surface is not smooth

I am building a Skerry, and I'm trying to finish up the exterior. There are several coats of epoxy, and I've just sanded. Two problems:

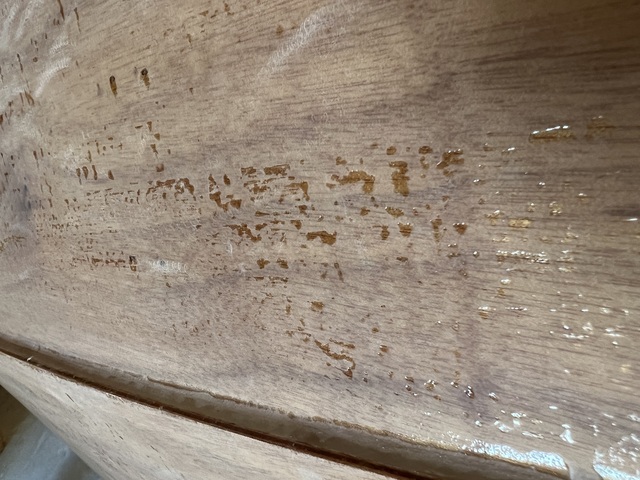

1) There are a few areas where the epoxy is uneven. You can see this in the photo below, where most of the surface is cloudy due to sanding, and then there are some imperfections where the epoxy is thinner and was not sanded. Before sanding, I tried to even these out with more epoxy, but that doesn't seem to have helped, perhaps the new epoxy covered everything evenly, leaving the problem intact.

Is this problem cosmetic only, or could it lead to problems down the road, once the boat is painted? Even if the problem is just cosmetic, I'd like to get the surface smoother.

2) Here you can see a couple of oval shaped areas where the grain of the fiberglass shows through. I don't believe the fiberglass is coming through the epoxy there, I can't feel that texture. So I'm not sure what the cause is. (And to the left of those ovals, you can see more of those unevenly filled areas.)

Is this a cause for concern?

10 replies:

RE: Trying to finish up sanding of exterior, surface is not smooth

The ovals look as if the glass floated (too much epoxy locally), formed a bubble and the top of the bubble was sanded off.

You can tell if you're into the glass by wiping the area with denatured alcohol. If the pattern disappears until the alcohol dries, you're almost, but not quite, into the glass. If it doesn't disappear, you're into the glass.Mummichog's advice to give it a light coat of epoxy is the way to go.

There's 2 ways to get rid of the low spots. If you're painting there, the easiest way is to use epoxy/microballoon mix, or some other fairing compound, and a longboard.

If that's meant to be varnished, you need to fair it with unthickened epoxy. As deep and widespread as they are, It'll take at least 3 coats to fill those in. Use very thin coats, apply only in the dimpled areas and sand with #220 paper. Once they're filled in, a final coat everywhere and sanding will have you ready for varnish.

I've had surfaces like that and gotten them smooth and flat, but it takes days. If you don't want to take the time, as long as the surface is sealed you'll be fine.

Laszlo

RE: Trying to finish up sanding of exterior, surface is not smooth

I am very curious as i cannot see any pictures above.....or indication of a picture i can't see.....

can anybody inlighten me if i am having a technical issue?

h

RE: Trying to finish up sanding of exterior, surface is not smooth

Thank you, Mummichog and Laszlo. I ran across another recent question, asking about the same issue, and it mentioned fairing compound and a longboard.

Hspira: I host the photos on my low-end AWS instance. Perhaps it was just sluggish? Can you try again?

I actually wrote to the forum about this issue (the first one) before sanding, and hoped that sanding would clear it up. Oh well. I do plan on painting the boat, as that will cover up my many, many mistakes. So I'll try fairing.

RE: Trying to finish up sanding of exterior, surface is not smooth

One more question, about fairing: The adhesive-backed sandpaper is quite expensive, so I'd rather not buy multiple rolls. What do you recommend, 120 or 220? I'm thinking 120 applied to the longboard to get the imperfections filled in, and then hand sanding with ordinary 220 sandpaper.

RE: Trying to finish up sanding of exterior, surface is not smooth

I made my own longboard for the SUP because of larger flatter surfaces. I cut out a piece of thin plywood, but should have used thinner because it needed more give and glued on a couple of handles from scrap wood. But I got a couple of plain belt sander belts, the longest I could and cut them and used spray adhesive to stick them to the board. I think they're 120 grit. Vacuum them out (if you are dry sanding) often to make them last longer. On the skerry I just used my foam blocks and sticks or dowels for tight places with paper wrapped around them. I did use the orbital sander on the bottom and seats, attached to the shop vac w/ HEPA filter but on the hull planks, there's just too many corners and curves for me to use the power tools.

RE: Trying to finish up sanding of exterior, surface is not smooth

apologies.. still can't see any evidence of a picture above (using Chrome browser and MS Edge on windows 11 computer). but can see them on an iphone using safari. strange...have never had quite that problem before.

just wanted to add that i have made a longboard before for faring and it worked great. i made a strip of 3/16 ply x 3 inches X 22 inches and used an inexpensive spray adhesive and glued two pieces of 80 grit sanpaper to it (11 inch length X 2).

emphasis on the word 'faring' for making fare surface (no broad divits or bulges) so i think of faring as an agressive but controlled form of cutting. then i followed it up by hand with 120, 180, 220 etc to take the scratches out. basically it sounds like i did what mumichog did....quick pictures below...bit of a mess in the shop so did not take any time to stage these pictures or clean up :)

h

RE: Trying to finish up sanding of exterior, surface is not smooth

Howard,

The images are at http://geophile.com/boat/clc/f3.jpg. Try loading it directly into a new tab using the link. You may get a useful error message that way. I'm guessing that it's a firewall issue.

Geophile,

As far as paper, I bought a roll each of 80, 120 and 220 some years ago. I still have most of each. They're very high quality and a roll lasts a long time, so if you can afford the upfront cost you'll save money over the long run as opposed to DIY store paper.

If that's not feasible, then Howard's trick about using spray adhesive to hold DIY store paper on is less upfront cash.

I'd say try a sanding block with 120 and if it's too aggressive go to 220, then order what worked best.

Finally, I like the longboard for sanding beyond fairing because it maintains the smooth surface better, but if you're good at controlling the sanding block you can do without for the final grits.

Laszlo

RE: Trying to finish up sanding of exterior, surface is not smooth

Hi Laszlo,

am able to see it from the link you posted with no problem....hmmmm

the only thing i can see is that when i hit your link directly i also get a warning 'not secure' which i don't get from the CLC site (but i also don't get a picture...) so i wonder if there is a security setting that prevent referral/exposure of unsecure embedded links but allows it if you explictly go to it?

h

RE: Trying to finish up sanding of exterior, surface is not smooth

Howard,

That sounds about right. The "not secure" warning is because it's http instead of https.

Laszlo

RE: Trying to finish up sanding of exterior, surface is not smooth

» Submitted by Mummichog - Sat, 2/12/22 » 11:02 PM

Where you see the white weave, you have likely gotten down to the 'glass itself. I wouldn't go any farther. You won't feel the weave since it's embedded in the resin and you are sanding the whole matrix together. I might go back w/ a thin coat of epoxy to make sure I sealed those places up.

I don't have any great answers on the little depressions. I have them on my skerry. I think you are right that rolling more neat epoxy on will build up everything, not just the low spots. I wound up deciding to live with them and used a little Interlux Flattening Agent in my Brightsides paint to reduce the gloss some and make such things less obvious. On a recent SUP, I wound up using phenolic microballoons to fair in some slightly deeper low spots, which meant using the squeegee to spread the fairing mix on then sanding it down. Stand back a few feet and you'd have to know what to look for on my skerry to find those spots. I'm just not a sander type, so I said good enough.