Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

How long to cure epoxy in a cold garage?

I wanted to share my basic solution to this problem in case it’s helpful to others, and start a conversation about ways people have thought of to speed up curing.

I’m building a skerry in Colorado, and the temperature fluctuates quite a bit between day and night.

I got a $30 wifi temperature logger (Grovee) and found that the temperature in my garage (on my skerry) also fluctuates a lot more than I thought—only some 10 degrees different from outside, so 40s - 70s within 12 hours, depending on the day.

Space heaters do help, but I’m wary of running them for too long when I’m at work or asleep.

I wrote up a simple script to take the temperature logs from the temp logger, and calculate the equivalent curing time my epoxy would be at if it were at 75 degrees instead of changing so much. I’m just using the double curing time every 10 degrees colder in a continuous fashion. It spits out plots like this:

You can see how the 75 degree curing time goes up faster as the temp goes up, and starts counting at the time I tell it I put on the epoxy.

I’ll attach the code below. The log files are just .csv files, so it would likely work with many loggers, not just the Grovee. I used matlab because I have free access to that, but it would be easy to do in python for anyone so inclined. The main difference would be in how you select the starting time. In mine I click on the plot to get the first data point. Worse case alternative is that it could easily be looked up on the log file, and then just use manually enter the corresponding index number of that time and temperature datapoint.

I hope this is helpful. What have other people found as effective ways to control/stabilize the temperature of an unheated workspace and not worry about an unattended space heater burning your boat down?

9 replies:

RE: How long to cure epoxy in a cold garage?

I don't understand what the graoh is saying. I get the temperature fluctuations (blue line), but what exactly is the orange line telling us? How much longer from a particular point in time till the epoxy is cured? If so, I would expect a diurnal fluctuation in the orange line that is related to the daily temps with a decrasing value that goes to 0 when the epoxy is cured. Instead, it's monotonically increasing.

Or is it telling us something else that I'm missing?

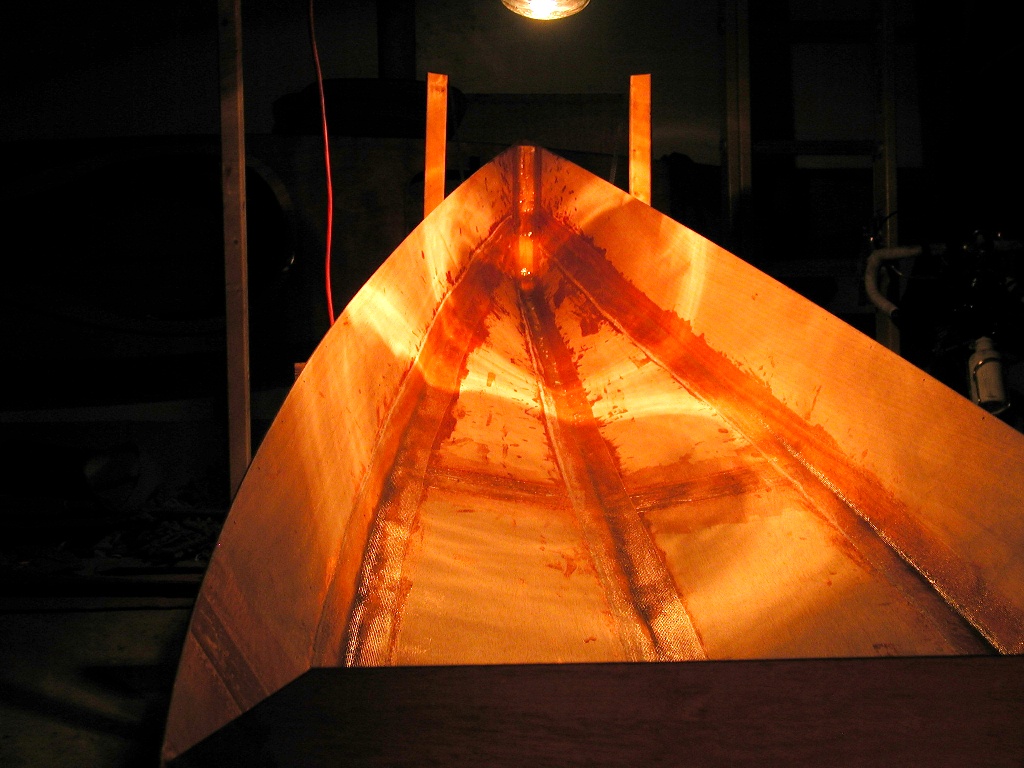

As far as controling/stabilizing the temperature, I used a heat lamp.

Others have also build a plastic tent over the boat and heat lamp to trap and hold the hot air after the lamp is off. Then there's always warming the epoxy in a bucket of warm water before mixing it. That gets it warm enough to start the reaction which, being exothermic, will keep itself warm and going at any sane temperature.

Laszlo

RE: How long to cure epoxy in a cold garage?

Hi Murm,

i am pretty sure i understand the graph and methods/math. i havebuilt through the winter before in an unheated garage....so i get the issues.

that said, there are a couple things i would point out similar to laszlo's comments.

first, regardless of the temperature fluctuations in the unheated space, i would always keep my epoxy in heated space and have a defined target mix temperature (i like to keep that tatget mixing temperature at 80 degrees). it makes a big difference in the viscosity and ease of mixing and the ability to get it to kick reliably.

on the ways to efficiently heat an unheated space, i find a plastic tent to be very effective. i too worried about burning my boat down so i built a wooden box for the task that fits around my electric space heater which ensures that my plastic tent will not come anywhere close to a hot element. i also don't tend to like it running unattended, but if you can get to the initial cure (where it is solid to the touch) then you can let the temperature fluctuate and it will just acheive its final cure a couple days later than if you kept the epoxy warm all the time, note, if you look at the MAS site, that the 'thin film set time' at 5 hours at 77 degrees which corresponds to what we typically say is 'cured' but notice the full cured time is 5 days. so if you keep your tent at 77 degrees you only have to maintain that for 5 hours and your main job is done and then you can just take your time on the full cure.....

anyway, those are some ideas i thought would be useful to share.

h

RE: How long to cure epoxy in a cold garage?

OK,

With a night's sleep I think I now understand the graph.

The orange line is the equivalent curing time experienced by the epoxy, not the predicted curing time for the epoxy, right? So what the graph is saying is that if the epoxy was applied at 23:47 on October 27th, at midnight October 29th it should be as cured as if had had 11 hours of cure at 75 degrees, right?

If so, I'd take that with a grain of salt. First off, the cure time is non-linear with temperature, asymptotic to infinity as the temperature goes down. The cure rate is asymptotic to zero as the temperature approaches a critical value. The exact coefficients depend on the chemical formulation of each particular epoxy. Second, mechanical factors get involved, factors that have a temperature-based effect. For example, stirring. Cold epoxy is more viscous so it requires more mixing to get the reactants into close proximity with each other. "Walls" of hardened epoxy can insulate pockets of unreacted epoxy and hardener so that you end up with a spongy structure containing liquid reactants (at a microscopic scale) which have a very negative effect on fatigue resistance. Because of these issues and others, it's best to consider that graph a first approximation and not depend on it, especially when temps get below 60.

On the other hand, if you can come up with a better approximation for effectiveMultiplier taking all this into account that'd be a pretty cool project.

Laszlo

RE: How long to cure epoxy in a cold garage?

Thanks Laszlo and Hspira for the comments.

Laszlo, appologies for the lack of clarity--I think your idea of plotting it as a countdown is slicker. You're right that the orange curve and right y-axis give the equivalent curing time at 75 degrees, and the cure is done when it gets to 24 hours.

I like the idea of the heat lamp--I bet those are safer, and will heat the surface locally rather than heating the air, which seems less efficient.

Also good to know the reaction is exothermic--I didn't realize that it produces enough energy to keep things moving at colder temperatures. I have observed that the epoxy seems very rigid at earlier times than the model predicts, and maybe that's why. Maybe that's also just the different timescales hspira mentioned. (Also there's likely a pretty intense temp gradient in the garage space).

The model is nonlinear--it is identical to the double the cure time every 10 degrees lower than 75 degrees rule of thumb, so it's certainly not worse than that. I imagine it no longer models the glue well at temps lower than 50 degrees or something, but the cure rate at those temperatures is so slow in the model that it doesn't make a big difference for the final number it spits out. I agree that it should be taken with a grain of salt if your workspace is consistently cold. But if it swings up in temperature during the day, I think this is better and easier than doing something like adding the number of hours it was around 75 degrees, and then half the number of hours it was around 65 degrees. To the extent that there's a better temperature model for a specific epoxy, you're right that the changing the effectiveMultiplier definition to that relationship would make this better. The only thing my simple script really solves is keeping track of the temperatures over time in a fine-grained manner.

I also didn't know the mixing was so temp dependent. I thought the issue with cold epoxy is that the metered pumps take longer to refill, and could give you the wrong ratio if you jump the gun on the resin--but if you were good an patient, it would work out fine. That's good to know, and I'll keep my glue warmer--maybe bring it in the house each night.

hspira, What do you mean kick? Is that the metered pumps working correctly or the chemical reaction starting? Good to know the importance of keeping the epoxy warm. When you talk about the main cure being done in a few hours, and then waiting out the rest, what do you change in that time? I imagine a 5 hour cure isn't enough before removing the stiches from the tack welds for example, or something else that would load the fresh epoxy joints.

But then in the instructions after filling in the laps the rest of the way, it says to let it cure for 24 hours before flipping it over and filleting the stems. Do you think it's fine to flip it with the tack welds doing a bulk of the structural holding, and moiving on with the seams? Or is flipping too much a stressor on those partially cured joints.

Haha, this happens to be the question in my mind right now as I plan my Sunday...

I keep wondering how they manage to put these together in a week. I imagine they must skimp on some of the 24 hour waits in the instructions, or combine steps in a way I'm not thinking.

Very excited my Skerry is looking more and more like something I could climb in.

RE: How long to cure epoxy in a cold garage?

Sorry Laszlo I didn't answer your question directly--yes you're interpreting the graph correctly, but for some reason the tick marks are at midnight, rather than the middle of the day (I find this confusing). So at midnight on the 29th it's more like it had only cured 8 hours at 75 degrees, rather than 11.

RE: How long to cure epoxy in a cold garage?

murm wrote >> I keep wondering how they manage to put these together in a week. I imagine they must skimp on some of the 24 hour waits in the instructions, or combine steps in a way I'm not thinking.

The instructor and CLC staff do a bunch of the steps for you the weekend before the class starts. For example, all the puzzle/scarph joints on the strakes are glued and cleaned, extra thick pieces of wood (transoms, skegs, rudders, daggerboards, etc.) are pre-laminated and cleaned and so on.

The classroom space is temeperature controlled.

In some cases I've heard of the pre-work being done by the experienced instructors using fast hardener.

The assembly is carefully planned so that cure times on one piece overlap with the work time on another so that by the time you need a piece it has cured solid in the temperature-controlled shop.

RE: How long to cure epoxy in a cold garage?

Murm,

I think your range of temperatures is actually quite workable the way it is. I would probably just use fast hardener when it's below 55 or 60, and medium if it's between 55 and 70 (or you can mix fast and slow at a ratio that feels right).

RE: How long to cure epoxy in a cold garage?

Thanks Laszlo, this makes me feel much better about my much slower pace. I don't mind it, as it's all new to me, but I don't feel like I'm quite so slow.

Thanks Andrew, I wanted to avoid the exoxy blushing, as that sounded annoying and kind of gross, but maybe it's less annoying to use faster-curing stuff. I'm going to stick with the slow hardener for now as I'll end up letting things sit for days between working on it anway, and probably the longer pot life is nice for me as a beginner as I figure out how to 'glass and things as I go.

I got a heat lamp, keep my epoxy in the house when not using it, and have been using the script to ballpark where I think the cure should be at, and all has been going well so far. Thanks for all the feedback everyone.

RE: How long to cure epoxy in a cold garage?

» Submitted by murm - Sat, 10/30/21 » 10:32 AM

And here's the script:

%% load, prepare and plot the temperature data

filepath = '/Users/max/Downloads/';

filename = 'Wifi Thermometer_export_202110300730';

data = readtable([filepath filename '.csv']) ;

clear effectiveTimeHours times temps time temp

% preallocate for the variables

temp = zeros( 1, height(data) );

time = NaT( 1,height(data) );

for it = 1: height(data)

temp(it) = table2array( data(it,2) );

time(it) = table2array( data(it,1) ) ;

end

fig = figure;

yyaxis left

plot(time, temp)

ylabel('temperature (\circF)')

xlabel('time')

%% ask for the start time

% get the starting index from the user by the cursor

dcmObj = datacursormode(fig);

dcmObj.Enable = 'on';

input('Click the start time and hit enter.')

cursorInfo = getCursorInfo(dcmObj);

pos = cursorInfo.Position;

startTime = datestr( pos(1) )

index = cursorInfo.DataIndex;

%% Calculate the integrated 70-degree-equivalent elapsed time until now

temps = temp( index : end );

loggingEventsPerHour = 60; % for 1 datapoint per minute

effectiveMultiplier = 2.^( (temps - 75) / 10);

effectiveTimeInHours = sum(effectiveMultiplier)/loggingEventsPerHour;

fprintf( 'The epoxy should be cured as though it spent %.1f hours at 75%cF\n', ...

effectiveTimeInHours, char(176) );

%% Plot the integrated equivalent elapsed time

effectiveTimeHours = [ 1: length(temps) ];

yyaxis right

for it = 1: length(temps)

effectiveTimeHours(it) = sum( effectiveMultiplier(1:it) )/60;

end

times = time( index : end );

figure(fig)

plot(times, effectiveTimeHours)

ylabel('equivalent curing time at 75\circF (hours)')