Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Making a new Daggerboard (or foiled again)

Having developed a little feel for what my boat is doing it’s become clear my daggerboard and rudder aren’t helping as much as they could. I should say lifting, sagging down to le’ward isn’t much fun. I didn’t do a very good job shaping the original daggerboard so I’m making a new one of solid wood. It’s a pretty common technique apparently.

I cut a bunch of staves, glued up a blank and made it true and planar. Finished thickness is 1/8” more than stock to allow a tad more shape and still fit the trunk.

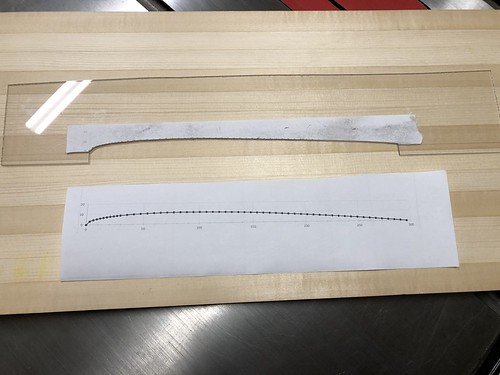

Found an online tool to create a NACA 000 profile for the thickness and cord of my blank. Took the coma delimited data into excel and plotted a graph.

Printed, stuck it to plexiglass, cut it out with a bandsaw and carefully worked to the line with a file. Should make a pretty reliable template.

So far so good. My questions are:

When shaping the bottom edge how abrupt should the transition be? Some high performance foils on the internets aren’t tapered at all at bottom edge. Info I’ve seen indicates round overs cause drag. Is there a tradeoff with turbulance and damage avoidance?

The leading edge bottom corner needs to be rounded to reduce damage, plan to duplicate the radius of original board unless someone has a better idea. Will also radius the trailing edge.

Finally, does the transition from foil section to flat section take place inside the trunk or just outside? It seems to me having the transition happen inside the trunk would cause a hollow and a great deal of drag. Also, having the very thin trailing edge bumping against the trunk housing would damage both.

I’d be happy to hear from y’all who’ve actually build daggerboards like this, thanks,

e

5 replies:

RE: Making a new Daggerboard (or foiled again)

Looks like I timed out. Here are the last two pictures.

RE: Making a new Daggerboard (or foiled again)

So, I've not made a solid wood foil, only plywood ones. Here's the rudder from my schooner:

It's a true NACA-style foil. The plies/contour lines show you what kind of shaping I did at the edges. That's a grass shadow at the lower trailing edge, not a break in the wood.

The bottom is a smooth transition. While it is true that the tip of airfoils is where induced drag occurs (because of the redirection of flow causing tip vortices), not rounding over the tip will cause even more drag as the flow abruptly comes off the tip and stalls. If you're concerned about induced drag the actual solution is to either add an orthogonal plate at the tip or to make the blade longer. That's what the high-efficiency aircraft do - winglets or high aspect ratio wings or both. They never end just squared off.

My feeling is that for a dagger board you're already at a good aspect ratio and if you make it longer it will be unwieldy and/or mess up the balance. And a tip plate would keep you from removing the daggerboard. So I'd just round it over and leave it at that.

For the transition, the ideal would be to have a smooth fillet from the board to the hull, but with a moving part that's difficult. The F-14 actually had an inflatable bag to close the gap where its swing wing overlapped the tail surfaces when the wing was swept all the way back, but that seems a bit complex for a dory :-)

As a practical matter, you're going to have a drag-making gap no matter what. If you make the transition outside and make the fit in the slot tight enough, you'll get weed, rocks, sand, etc. in there and the board will jam. If you make the slot wide enough to prevent jamming, you'll get drag. Since you're gonna have drag either way, I'd say pick whichever works best for you. I've done it both ways and have not had damage issues.

Happy New Year,

Laszlo

RE: Making a new Daggerboard (or foiled again)

thanks for sharing your project.

as a starter, one of the challenges in boat foils - particularly small displacement (non-planing) boat foils, is that you are rarely going to acheive anything close to theoretical performance because the motion of the boat itself creates so much turbulence due to the boats reaction to wave motion and motion induced by your weight shifting (e.g., roll tacking). so while shaped foils are better than flat boards, some of the finer points like how to handle the end of the board will not likely ever be discernable outside of a test tank. (for background, i did some work in aerohyrdodyamics/boat hulls and windmills way back when) so you are looking at balancing a board that performs and has features that are also resistent to being easily damaged.

with that in mind, my suggestions relative to your questions:

first - the general shaping of the foil is going to provide the biggest impact. everything else you are describing is on the margin (probably undetectable) . but even a well shaped foil make little difference if it is not moving forward through the water (e.g., no wind or bad sailing techniques)

shaping the bottom of the foil: rounded over provides good damage protection and that is what i would go with. the next big step up would be a tip (look at the picture of a 737 max). but a tipped foil is not practical for most dinghlys. since folis are often rested on their bottoms or hit bottom, i would focus on damage resistence.

radiusing leading and trailing edges. your ideas sound fine.

transitioning the foil: i would make the part in the trunk shaped to the trunk shape and start my foil shaping below that point. it will help eliminate motion of the board in the trunk and be useful when you use kinetics (e.g., roll tacking) to move the boat.

i hope this helped.

h

RE: Making a new Daggerboard (or foiled again)

» Submitted by - Sat, 1/2/21 » 7:44 AM

Hello Silver Salt, I built the foils fopr my Goat using this technique following the directions from Michael Storer.

1. It looks like you already glued the blank, so this may be OBE, but using hardwood for the leading & training edge staves will make the board more damage resistant.

2. The leading edge of the foil should be rounded per the template.

3. Ideally, the trailing edge should be a knide edge but this would make it very fragile. Carve as thin as you want but make sure that the trailing edge is square. Rounding over the trailing edge will create drag.

4. Make a smooth round over along the entire bottom of the foil to reduce drag.

5. I basically made the entire length into the foil shape, but the trailing edge is a bit thicker where it sits up in the C/B trunk. I initially planned on leaving the upper portion above the water line square but found that the square area above WL interfered with planing the rounded area below.

6. If you want a more efficient blade, consider lengthening a bit and tapering the trailing edge to keep the same surface area. This will give the blade a higher aspect ratio.

7. Glass the tip first. When you glass the rest of the blade, told the blade horizontal and allow the glass to tounch below the trailing edge. When you trim it, use a plane so that the trailing edge remains square.