Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Hi all,

I've been sailing for a quite few years now, but have never built a boat before, and don't really have any woodworking experience either. So I decided to pick the smallest and easiest CLC sailboat for my first project—that appears to be Eastport Pram.

I am about to pull the trigger for the kit, and I am sure I'll have a lot questions as I go over it, but I'll start with these two.

I'll be building it in an unheated room over the Boston fall and winter, and I am getting concerned about epoxy curing (and paint and varnish, for that matter). Any thoughts or tips for that?

Also, for those of you who have build an Esatport Pram, any gotchas I should be aware of? I am thinking mostly in terms of following the instructions, but any tips for a complete newbie would be very much appreciated.

Andrew

7 replies:

RE: New to CLC / Eastport Pram

Hey Andrew,

I built the EP first, then a few years later built the Passagemaker. It's not any more difficult, so unless size, space or expense is a factor, don't let lack of experience stop you from building a larger boat. In some ways it's easier to bend longer planks.

Here's a link to my build videos: youtube.com/c/midnightmaker

And an Instructable: https://www.instructables.com/How-to-Build-a-Wood-Sailboat/

RE: New to CLC / Eastport Pram

Laszlo,

I actually have read their tips on epoxy in cold weather... They suggest using work lights to heat the boat, which sounds a little bit sketchy to me, especisally in the case of the entire boat... I wonder if anyone has actually tried it and how did it go.

They also mention elsewhere using fast hardener for epoxy—I wonder if that helps with cold and in what temperature range.

CaptainSkully,

Thank you for the write-up and the video! Very useful. I still think that I'll start with EP: it's fewer parts than Passagemaker, and less area to epoxy/finish (and to heat in the winter :).

RE: New to CLC / Eastport Pram

Andrew,

I've used both (lights and fast hardener) and they work well enough to build in an unheated garage in Maryland in parts of the winter, It never was cold enough to need the tent. Or rather, I was never willing to work in weather that was cold enough to need a tent so I never used one.

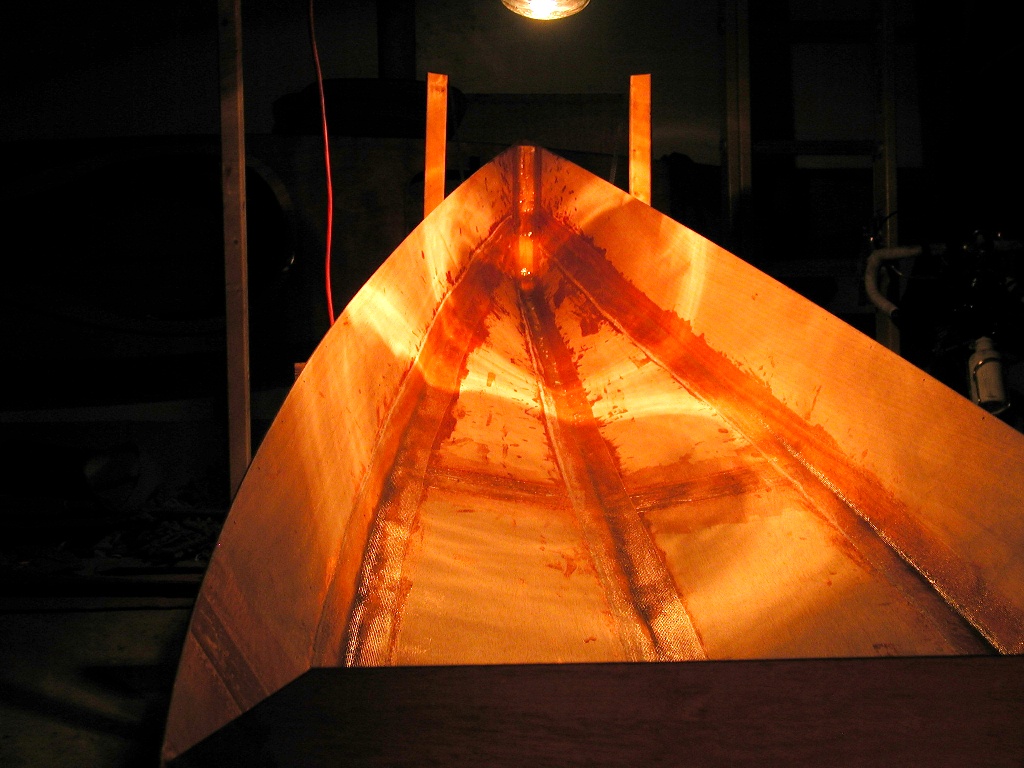

My WD12 being warmed under a heat lamp to let the epoxy on the fillets and tape cure.

The trick is to have the boat surface and epoxy and hardener warm enough for the reaction to start (around 60 degrees) and then it begins to generate its own heat until the reaction finishes. So all the lamps and heaters have to do is replace the heat loss. Fast hardener will allow the reaction to finish before all the heat is lost.

If you keep the epoxy & hardener in the house until you've finished mixing it and just take the mixed cup outside it'll have plenty of heat to start the reaction, to the point that you may not want to use fast hardener when you're laminating large sheets of glass fiber because it'll kick too fast. With keeping the epoxy/hardener inside and using the heat lamps, I've successfully built with an air temperature in the low 50's and even high 40's once.

Storing the epoxy inside will also keep it from crystallizing, which it does when it freezes. If the epoxy does crystallize, simply put the bottle into a bucket of hot (140 degree or so) water until the crystals melt. Do not use crystallized epoxy, it won't cure properly.

One unexpected Gotcha - it's getting hard to get incandescent worklights at the local stores anymore. They're switching to LEDs that are so wonderfully efficient that they don't put out 95% of their power as heat anymore. Great for the lighting bill, bad for using lights as gentle heaters.

Hope this helps,

Laszlo

RE: New to CLC / Eastport Pram

Laszlo's comments above reinforce exactly my experiences when I started my waterlust build just under a year ago in my 'mildly' heated garage.

Working under conditions like this it's important to bring everything up to 60 with enough time for any outgassing to finish, and that your fresh mixed epoxy's been prepared at 60 or better so not only the reaction begins early but also it's liquid enough to make a good bond with wood fibers and especially with 'glass cloth of any weight.

I used more fast hardener by far than slow getting to the 3/4 point in my build when weather outside finally got stable enough to leave the garage heater off.

RE: New to CLC / Eastport Pram

This helps a lot, thank you. Storing (and mixing!) epoxy indoors makes perfect sense.

What about paint and varnish? Do they also need certain temperature to cure properly, or it's just going slower when it's cooler?

RE: New to CLC / Eastport Pram

In a word, yes.

Paint and varnish - the traditional stuff at least, what I'm familiar with - are 'chemical' in nature in that they're a combination of solids and solvents that make up the mix you're applying.

Epoxy's a whole 'nother ball'o'wax when it comes to chemistry, rest assured! Why you need to understand what the manufacturers' recommend as far as working conditions under which the tuff will either work, or may not.

Paint and varnish need to be warm enough to apply smoothly, and the substrates they're being applied to must also be 'conditioned' to the ambient temperatures under which you'll be working. Otherwise you may have moisture condensation issues (cold substrate, your warm breath condensing moisture as you breathe onto the surfaces) or the stuff you're applying begins to harden / dry while you're applying it (too warm substrate, maybe too thick a finish coat).

Too, they both need to have sufficient time + temperatures to allow both the solvents to evaporate and the vehicles in which the solids are suspended to oxidize, which creates the final finish characteristics you want from them.

Too cold for either, the solvents take forever to leave and that oxidation is drastically slowed down, to the point it can take X number of times longer to dry and cure properly than if a more reasonable environment was achived for their application and dry-time.

Humidity's a big deal with both varnish and paint. One needs to pay attention to what the manufacturers' recommendations are for best results, as with epoxies.

RE: New to CLC / Eastport Pram

» Submitted by Laszlo - Thu, 10/8/20 » 7:03 PM

Welcome to the mob!

The Eastport Pram is a fun little boat to sail and small enough to be easy to move and store. A Boston winter will definitely challenge your epoxy, varnish and paint. At the top of this page is a button labeled "Tips for Boatbuilders". Read as much of that as you can before you start building, it's full of valuable info. Specifically, it has a section called Epoxy in Cold Weather which should help you deal with old man Winter.

Have fun,

Laszlo