Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Skerry: Attaching #2 panel to #1 panel -- close but not quite right

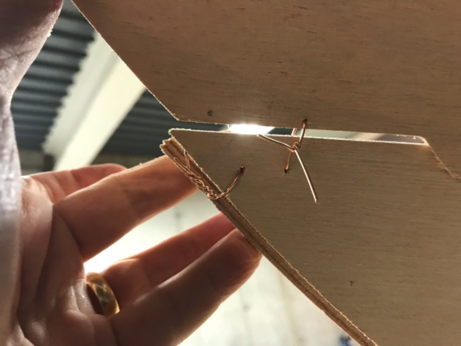

I have wired the #1 panels and frames to the bottom panel. I am now trying to wire in the #2 panels, and things aren't quite lining up. As described in the manual, I started at the bow, and worked my way to the stern. The stern end of the #2 panel is a couple of millimeters short (see attached pictures -- Stern end, outside then inside; Bow end, outside then inside).

I called CLC support, and they said to start over, wiring the middle first, and then the ends. For the life of me, I cannot get both ends aligned properly at the same time. If the stern is aligned, the bow end is a bit short, and vice versa. It's as if the #2 panel really is just a tiny bit shorter. I suspect what's really going on is that the #2 panel is sagging a bit somewhere causing the panel to be "short" at one end. I only have a few ties in, allowing me to pull the panel a bit to match at one end. But then it's short on the other end.

Any advice on how to proceed?

6 replies:

RE: Skerry: Attaching #2 panel to #1 panel -- close but not quite right

My memory works poorly, according to my mail exchange with John Harris (2013), panel # 1 was the problem.

Johns answered:

Well, the bottom panel is SUPPOSED to bend in a gentle arc from bow to star, so that sounds correct. As you continue to add planks and the structure gains more rigidity, gaps will gradually disappear and everything will line up smoothly. And remember, all seams are filled with epoxy, so minor gaps are nothing to be concerned about!

I put the boat on 2 sawhorses and got more sagging. I supplemented the panels that remained a bit too short with epoxy.

Ruud

RE: Skerry: Attaching #2 panel to #1 panel -- close but not quite right

I couldn't get my top panels (#3?) to meet at the stern. I wasted a fair bit of copper wire re-stitching and still couldn't get them to meet up. As I was always going to paint her, I shaped a block of wood and glued it in the gap. That was 5 years ago. The boat is fine. :-)

Very few people ever knew (more now of course) and you can't see it despite painting not being my forte. Photos are available on request.

RE: Skerry: Attaching #2 panel to #1 panel -- close but not quite right

Thanks everyone. Between these responses, and a couple of calls to support, I have the #2 panels attached.

RE: Skerry: Attaching #2 panel to #1 panel -- close but not quite right

When I told by the staff on the supervised Skerry building week that quite large gaps were 'normal', I was rather disappointed. You come to realize the CLC building method is as minimalist as it gets and that the absence of any structure to help form the shape, such as molds or a strongback, mean that forming the shape only by folding together some thin ply planks is bound to be a bit hit and miss. I dare say no two boats built this way are exactly alike. In the end I’m sure it makes no difference to strength or performance of the finished article but i remember that sinking feeling from the sense I was bodging things up right from the outset by needing to form my bow and stern from thin air and thickened epoxy.

RE: Skerry: Attaching #2 panel to #1 panel -- close but not quite right

During our class we stiched up the whole boat and flipped it, there were big gaps. After the flip we went through the entire boat again using pliers on the copper ties to pull and twist tigther as we pushed the panels tighter into place. That closed most of the gaps down but there are still some that are just expected to exist. It would of been difficult to close them down as much as we did without two people and we of course broke a few copper ties in the process which is fun.

The wood flour epoxy mix fills the gaps in but also the bow and stern will be covered in fiberglass up to the breasthook.

RE: Skerry: Attaching #2 panel to #1 panel -- close but not quite right

» Submitted by ruud - Thu, 9/26/19 » 6:19 PM

I had the same problem. What helped was to put the boat on 2 sawhorses and let it sag a lot. The sagging is important. However, I still had slightly too short panels (No. 3). I believe I finally shortened the other 2 panels a bit and filled the short panels with epoxy. I painted the outside white. And on the inside, the problem area fell exactly under the bresthook.

Ruud