Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Cutting multiple parts at same time WD12

Building my first stich and glue (WD12) from plans. Has anyone cut muliple parts at once - traced with holes (ice pick) connected by pencil lines and then cutting two parts at once - say both bottom panels at once - all the make "two parts" together.

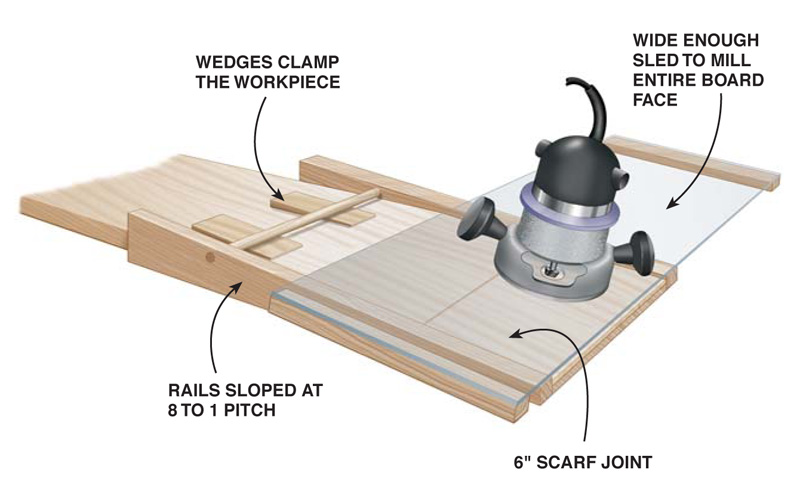

I would also like to make a jig and router my scarf joints - any suggestions for a good jig?

6 replies:

RE: Cutting multiple parts at same time WD12

Same here for my scratch and plans builds. First I laid out one piece carefully, then I used wire brads to attach it to another sheet of wood (clamps are too easy to accidently open). After that it was cut outside the line and then bring the edge to the line with a rasp. The holes from the brads are tiny and get filled in when you epoxy the wood.

Personally, I find scarfing easiest to do with a hand plane. The plywood layers give you a set of built-in guidelines that let you do a perfect scarf. If you do want a router jig, just google "scarfing jig" and you'll get millions of results. Here's one basic one:

Have fun,

Laszlo

RE: Cutting multiple parts at same time WD12 part 2

Thanks all - great stuff - I am at the fist cut stage and a little nervous. Wondering if any of you have made a master masonite template using the stick the plan to the masonite material technique then cut the final finished marine ply part using a router and collared cutting bit? Lots of dust and more waste, but pretty accurate and quick to repeat. CaptSkully - it sounds like what you do - do you make the form first - or cut all three together - if I read your post correctly you cut all three at once? Also no adhesive residue to worry about on the acutual parts. Jig saw? and/or circular saw?

If I love the first version of my WD12, it would be nice to be able to knock out a twin easier, I made the forms that way using scrap Luan Ply and reinforced them with narrow moulding strips - cut them with my bandsaw because they were small enough to turn.

RE: Cutting multiple parts at same time WD12

I've always skipped the patterns and marked directly on the wood from the measurements in the plans. Stacking the mirrored pieces saves time, but for building just one boat it's slower to do all that pattern stuff (paper or masonite) and I've never built 2 of the same boat. If you do build a second one, don't forget to send CLC the additional license fee.

Have fun,

Laszlo

RE: Cutting multiple parts at same time WD12

Yes, for both single parts (e.g. bottoms) or symmetrical parts (e.g. planks), I cut out a masonite template at the same time I'm cutting out the part on the mechanical pencil line from the plans. There is no tape or adhesive, but I do use a drywall screw through the waste to hold the layers together. Single parts have two layers and symmetrical parts have three layers. Screws through the hand hold cutouts are very useful and can be cut out later. I use a cheap $11 Harbor Freight pull saw to cut out all my parts. The masonite dulls them pretty quickly.

One of the main reasons I make template parts is so that I can make a 2nd boat in about 20 hours less time (although I haven't done it yet). I'm a woodworker, so router templates are nothing new to me, so I thought that would be the perfect application. Yes, you rough cut the part out with a jigsaw and then affix the template and route the edge to get a perfect copy. On my first plans built boat, I wasn't sure how it would turn out vs. a CNC kit, so I was a bit hesitant, but the boat stitched together perfectly.

There's also the possibility of building multiple boats for a personal fleet or for sale. I've thought of trying to sell one boat to pay for building two. With the template system, I could easily build two EP's side by side and the "profit" on the sold boat could cover the materials of the first boat. In my experience, there's a lot of down time waiting for epoxy to cure, so that could be used by repeating the same step on a second boat.

Either way, with the set of templates for each boat I've built, I feel like I'm building a "stable" of boats that I can easily reproduce as needed. Of course, this brings up the topic of royalties to be paid to CLC, which is another subject alltogether and something I haven't had to broach yet.

RE: Cutting multiple parts at same time WD12

Woodboy

I find it faster to use a Stanley No 4 Handplane to make the scarf joints. Watch the glue lines on the plywood, if they are straight your scarf will be accurate. See the link to a photo of the hand planed scarf on my Sassafras 16. Jigs are somewhat labor intensive.

RE: Cutting multiple parts at same time WD12

» Submitted by CaptainSkully - Fri, 9/21/18 » 11:05 PM

Are you talking about making two symmetrical parts at the same time to build one boat or are you talking about making two boats at the same time?

Either way, yes, you can cut multiple parts out at the same time with stacked materials. I've done symmetrical parts with stacked plywood and I've also made templates for both boats I've built while the actual marine grade plywood was stacked with masonite (tempered hardboard). Either way yields parts that at least if they aren't exactly to the plan are at least symmetrical, which will give you a better boat than if port and starboard parts are different due to separate layouts.

Does that answer your question?