Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Eliminating bubbles when rolling on unthickened epoxy

I thought I was rolling on very thin layer of unthickened epoxy for my Passagemaker hull panels but they have dried with lots of small bumps. Too much stirring, wrong rollers (I used disposable foam), need to brush it out AFTER using rollers?? I removed all dust and wiped them down with denatured first. I know it gets sanded in between layers but want to eliminate as many of these as I can. Thanks!

10 replies:

RE: Eliminating bubbles when rolling on unthickened epoxy

Do this, and eliminate the bubbles to a large degree:

Roll the unthickened epoxy using West Systems 800 foam rollers. After you have rolled it out to your satisfaction, take a heat gun or hair dryer and waive it over the rolled area. You will be able to see the bubbles pop from the heat, which is applied ever so briefly.

If you were applying the epoxy over unsealed wood, you may also have experienced "off-gassing", which occurs when the temperature is rising. I always heat my shop and then shut the heat off, allowing the temp to be falling as I apply the seal coat of epoxy, which will avoid this problem.

Sean.

RE: Eliminating bubbles when rolling on unthickened epoxy

I am pretty sure Nick has a utube video of the process at Guillmont Kayaks

Ed

RE: Eliminating bubbles when rolling on unthickened epoxy

Tip it out with a dry foam brush. Just a light brush of the tip against the wet epoxy and all the bubbles pop. Also works for paint, varnish; any rolled material.

Laszlo

RE: Eliminating bubbles when rolling on unthickened epoxy

Not sure if this technique works with MAS epoxies,

But i've seen other resins (think bar tabletops, other youtube projects, etc), where the epoxy was applied and then a small hand-held butane/propane torch (or other similar heat source, like heat gun) was used briefly passing over the surface to pop the bubbles.

It appeared to help level the resin as well (on those tabletop surfaces).

has anyone done this torch approach...? (other than the heat-gun)

as i only have a hair-dryer, no heat gun; but DO have a small butane torch.

RE: Eliminating bubbles when rolling on unthickened epoxy

A torch works well. Only risk is possible contamination from the fuel being burned. A heat gun would be a safer choice.

I’ve poured table top epoxy on a few occasions. A product called bubble buster eliminated all of the surface bubbles instantly. Not sure what it was made of but it didn’t contaminate the surface for the following pours.

RE: Eliminating bubbles when rolling on unthickened epoxy

I was also researching this, and with some experementing with a torch on some scrap found out how easy it is to singe the wood and discolor the epoxy (clearly I was too close and/or too slow).

I newly found another technique: use a very fine spray bottle to put an ever-so-light mist of denatured alcohol onto the surface of the epoxy. Supposedly has the same bubble-busting/leveling effect and evaporates off quickly, though this may be applicable to deeper pours. Anyone tried?

RE: Eliminating bubbles when rolling on unthickened epoxy

What Laszlo said...It's tried and proven many times over. Using a good quality foam brush is important. The box store types don't work very well. Jen brand is the best I've found locally - you can buy it at Ace Hardware. Big difference in performance...

Hooper

RE: Eliminating bubbles when rolling on unthickened epoxy

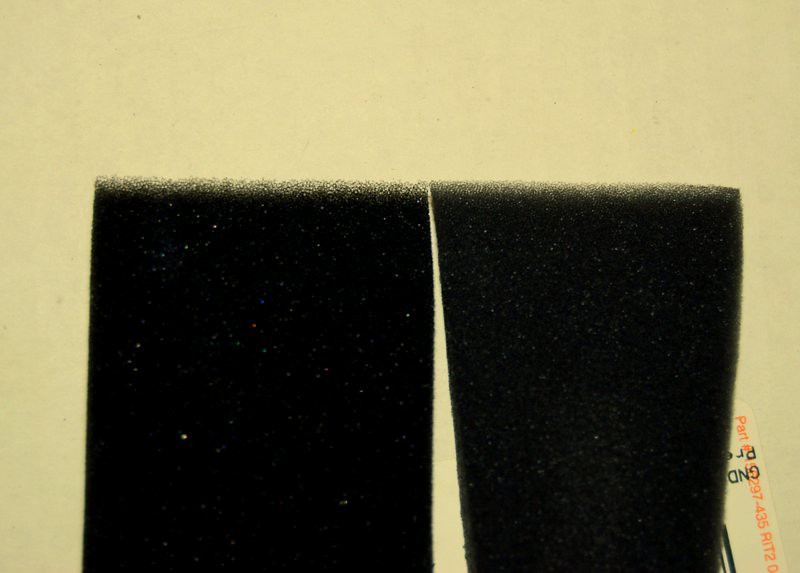

I forgot I had a picture. You can see the difference:

Hooper

RE: Eliminating bubbles when rolling on unthickened epoxy

Also, people want to squeeze the last bit of epoxy out of the roller, which causes the foam roller to burp all those bubbles out into the epoxy. That's a big mistake. Use light pressure when rolling, just enough to make sure you don't get sags. A little lost epoxy is worth the effort of getting rid of all those bubbles. As usual, Laszlo is absolutely right. I use a new, clean 4" foam brush to tip with every batch/application.

RE: Eliminating bubbles when rolling on unthickened epoxy

» Submitted by src321 - Wed, 2/7/18 » 12:30 PM

I had the same problem on my Chester yawl first few boards. You have to brush it out after you roll. No way to roll without bubbles. Get a chip brush and brush out really gently in long strokes and as soon as you can while epoxy is still very wet.