Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

I may buy a router. Never used one before. For building the NE Dory kit with lug rig, is a basic trim router good enough? Are there any must-have features for this application? I don't mind spending the bucks for good tools, but I don't want to buy something I don't need either. Less is often more in the world of boating.

12 replies:

RE: router advice sought

Depending on your experience, a router can be a great tool or a really bad tool. It is great for rounding over edges but can do A LOT of damage in a short amount of time. And I'm not just saying on the wood. As an ED RN I've seen nasty injuries. I used my router to rabbit the outer rail over the plywood on panel 1. Everything on my dory has a rounded over edge, do I used the router, hand sanding and block plane. The best advise I got was to use good bits, take small cuts and practice before you pick up the real piece, My router was a 30 year old 1 1/2 hp craftsman. I bought new Freud bits from Home Depot. Any power tool has a hand substitute, use what you are comfortable with and enjoy the journey.

RE: router advice sought

I used a plane, a spoke shave, some handsaws, and a circular saw to make all of my sailing components. I wasn't expecting perfection, but nobody seems to notice--or care about--the minor irregularities that hand tools will leave.

RE: router advice sought

I find that my router(s) work great on round overs if the two surfaces are at 90 degrees and I'm using a round over with a ball bearing pilot guide. Unfortunately, by design, there are few 90 degree angles in the boats I build. Using one without a guide produces a bumpy round over that has to be sanded to fix it anyway. Using a pin guide, without ball bearing roller, produces a burned edge, ugly. Generally I'd rather use a sander to produce the round over.

.

Using a round over bit in a router mounted in a router table can produce some good parts.

.

The router can be used if you plan to carve out an inlay but that is a higher level use.

RE: router advice sought

In sanders I'd use a belt or vibratory sander for round overs rather than a random orbitor.

RE: router advice sought

You should have some experience with your belt sander before bringing it near a boat or boat parts. It can eat through a lot of wood fast.

RE: router advice sought

I had a belt sander and sold it. Too hard to control by hand.

Just for context I don't own a plane or a spokeshave or the shinto rasp. Or a drill press. So I'm thinking a router with an optional plunger could be good.

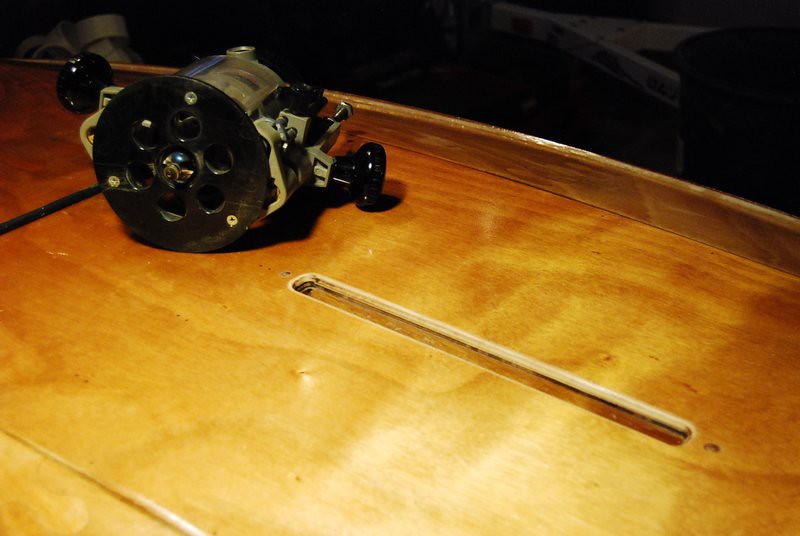

Birch2 the goal isn't really to get a "machined" look. The main use case for the router is cutting out the hull under the centreboard trunk. (Which sounds extremely scary!!!) I'm sure everything else could be done with hand tools or my trusty Bosch 1297D quarter sheet finish sander.

RE: router advice sought

I agree that a router is the easiest way to do this job, but not the only way. I also agree that it is kind of scary, but by the time you get to this stage you have realized that anything you can build, you can fix - so the extreme fear diminishes. I got rid of my plunge base. I never used it and the extra bulk and weight just made every other job more awkward. In choosing a router, you need enough power to safely do the job. Beyond that, the smaller the better.

Hooper Williams - Brevard, NC

RE: router advice sought

Hooper said, " You should have some experience with your belt sander before bringing it near a boat or boat parts. It can eat through a lot of wood fast."

.

I agree depending upon grit size, skill and application.

Many of my power tools and hand tools have been with me longer than my adult children and their children.

RE: router advice sought

I have a makita 700W RT0700C router and a big old plunge router. The old plunge router hardly ever gets used nowadays as the little Makita is a great tool. But the warnings above should be heeded - routers can do a fair bit of damage quite quickly but mine also made very short work on the Skerry side panel rebates and rounding over the rub rails. I wouldn't be without it.

RE: router advice sought

Has anyone used a router with a flush cut bit and bearing to trim the deck to the hull instead of a saw?

I've trimmed a lot of laminate and it seems like it would work well

RE: router advice sought

Trick w/a flush bit is the fixed 90° angle between router base & bit flutes. It's uncommon that 90° is the angle between planking (pilot runs against) and decking (carries base) so one has to account for the changes in angle somehow.

Boatwork isn't quite like doing casework... thankfully.

Trimmers (as opposed to routers) come with a variable-angle base so that's one option. Such a base would have to be adjusted fairly often unless the included angle being trimmed to doesn't vary much over the length to be worked.

Best option might be to choose a flush-trim bit that allows using larger diameter pilot bearings, then selecting a pilot large enough so you're not flush-trimming. The consistent overlap left makes final clean-up with a block plane more practical.

Whether this is faster and/or more effective than just using a saw before finishing by handwork depends on the builder's skills and goals more than anything else I think.

RE: router advice sought

» Submitted by Wiewandt, Frank - Wed, 4/5/17 » 5:52 PM

John,

I pulled out my old '91 Makita plunge router for my Eastport Pram build. I doubt a basic "trim" router will do the job but I'm sure others with more experience will let you know for sure. I'll be usiing up to a 1/2" round-over bit for the Eastport & I'm not sure a trim router will handle that well.

I hadn't used the router in a while so I actually got some burn when I used it on the skeg. I remebered I had a variable speed adapter & slowed it down a little for the skids & everything went much smoother after.

I think the router will give a more uniform rounding of edges so I'm happy I have one rather than just sanding/planning them.

Building my pram is the first real woodworking project I've done in years so its been a slow re-aquaintance with my power tools. I bought a random orbit sander for this project & am REALLY HAPPY I did! :-) I already had a battery drill, battery driver, circular saw, scroll saw & router & have used them all.

Personally, I'd buy a regular plunge router or just rely on sanding/planing the edges.

Take care,

Frank