Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

I just joined the deck to the hull on my shearwater for the final time and am getting ready to proceed with the exterior glass & epoxy, epoxy, epoxy steps. I've heard about wet & dry sanding, but can't find much information to describe techniques & tips using this method. Can someone out there bring me up to speed on this?

11 replies:

RE: Wet & Dry Sanding?

There might be some new techniques that I'm not familiar with, but if this is the age old question of wet or dry sanding, its something like this....

Finer grades of sandpaper, starting at about 220, would clog up very quickly if not rinsed off regularly with a water hose or bucket of water. Coarser grades, like 80, don't clog up nearly as quickly, the paper gets dull before the grit is clogged if its sanding a dry substance.

Two different types of paper are used for wet or dry sanding.... 'open coat' and 'wet-or-dry'. Open coat paper is not at all waterproof, and disintegrates rather quickly when wet. Wet-or-dry is waterproof, but as the name implies, can be used with water or dry depending on the situation. Rougher grades are generally available only in 'open coat', as most people would not bother with the water..... while finer grades are more available as 'wet-or-dry'.

A good generalization would be that you can get to the varnish stage and have good results without doing any wet sanding, but everything after the first coat of varnish will be wet-sand, as the papar is fine enough that it would pretty much clog instantly without the water. Hope this helps!

RE: Wet & Dry Sanding?

Me again. You'll find a wealth of info here on finishing your boat:

http://www.clcboats.com/shoptips/finishing/

Cheers. Jerry

RE: Wet & Dry Sanding?

I'm at this very point with the Ches 17LT. Yesterday, w&d sanded the 2 x coats epoxy on the deck (to be varnished after hull painting is finished), and tomorrow will w&d the two coats of u/coat on the hull that I applied today.

The way I proceed is to use progressively finer grades of w&d abrasive paper, dunking and agitating the paper vigorously every few minutes (or when it begins to clog) in a bucket of warm water to which has been added a generous dose of dishwashing liquid. This cleans off the w&d paper between each bout of sanding. But be prepared to change the w&d paper occasionally - I have used a full sheet, cut into four pieces, to sand the deck, so that it always presents a 'fresh' face. I expect the same when sanding the rather softer undercoat later. When sanding curved surfaces such as a cambered deck, or the rounded edges of the deck-to-hull join, always place a household sponge of say 5 to 10mm thickness between the w&d paper and the sanding block - in this way the paper will pick-up the curve of the deck and not be inclined to sand a series of flats into the surface. Good luck - it's a critical step and maybe a bit laborious but one I find satisfying in the quest for that near-perfect finish.

Wordsmith

RE: Wet & Dry Sanding?

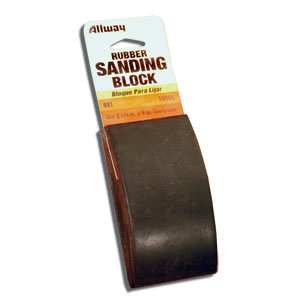

Speaking of sanding blocks, CLC sells this one:

It's waterproof and has a bit of flex, enough to avoid the flats Wordsmith was mentioning above (at least for moderate convex curves). I've used it to wet sand 3 boats.

For deep concave curves (like by the WD12 bow) I used a piece of closed cell foam for my sanding block. WS's sponge suggestion is a good one for folks who don't just happen to have chunks of minicell laying around the shop.

Laszlo

RE: Wet & Dry Sanding?

I prefer steel wool for the finish varnish coats. Usually go to a 0000.

I agree with the other comments on the finer grits clogging and hence cleaning them out by rinsing. It is also my understanding that the water provides some lubrication to produce an even finer finish. I'm a big fan of wet sanding for finishing, unless we are talking varnish as mentioned above.

RE: Wet & Dry Sanding?

Steel wool is great for terrestrial applications, but can be a problem for boats. Any bits of steel dust left in the varnish will rust and streak the finish.

Laszlo

RE: Wet & Dry Sanding?

We use bronze wool instead of steel wool for burnishing low friction bottom paint on boats. Never tried it for bright work. I think it would work just as well for varnish without the risk of rust.

RE: Wet & Dry Sanding?

I've been using scotch-brite pads to scuff up varnish. They work well and seem to be fairly widely recommended for this purpose.

--

Ogata (eric)

RE: Wet & Dry Sanding?

Thanks for the information. I have a lot of options based on what everyone has had to say about the subject. I am excited to get to this stage of my build and appreciate the guidance (education) you folks have provided. Mark

RE: Wet & Dry Sanding?

» Submitted by Jerry - Sat, 2/7/09 » 8:28 PM

Hi. Sanding with regular dry 150 grit on bare wood is about as fine as you need. Once you have the glass on with about four coats of resin built up to fill the glass weave, sanding lightly between coats with 150, you need to finish sand. Start with 150, go to 220 then wet or dry sand with 400 if you want. I stop at 220 on the resin and only wet sand with 400 (the black wet/dry paper that can be dipped in water) between the final four/five coats of varnish and have come up with a show-quality finish every time. Good luck. Jerry