Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

I plan on building the Peeler Skiff and notice on one of the pages in the tip section they talked about using copper wire vs. zip ties. I have a roll of .032 steel wire and wonder if I could use that instead of the copper wire. Any thoughts or suggestions on building the skiff

10 replies:

RE: Why Copper wire

I got my Peeler kit a couple of years back and it came with stainless wire. The side panels and bulkheads are 9mm ply, the bottom panels are 18mm and the curves are mild so there really isn't much chance of tearing out. After "tack welding" the seams there is no problem with pulling them out, especially if you heat the wires.

RE: Why Copper wire

SaSoLi,

As Catboater mentioned, our Peeler kits came with stainless steel wire. I had zero problems using it and had no difficulty removing it when the epoxy tacks set.

Have fun,

Dick

RE: Why Copper wire

Tacking the joints, removing the wires and epoxy over the holes makes sanding easier.

Zip ties are generally too big. Small zips break to easier.

RE: Why Copper wire

.....And once you tighten a zip tie you're done. With wires you may have to loosen, retie, etc to get the right shape.

RE: Why Copper wire

Zip ties do work better for thicker ply and bigger boats, especially over a little piece of pvc. Picasa pic linked below:

RE: Why Copper wire

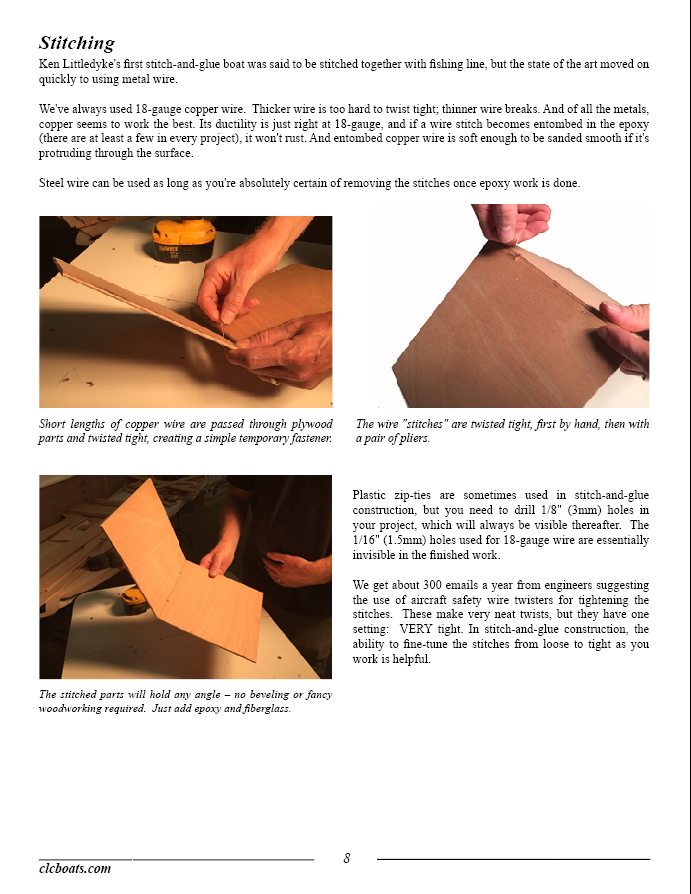

Some thoughts on copper wire, from the introduction to the Teardrop Camper manual. (Click to enlarge.)

RE: Why Copper wire

John,

Thank you for the reading material! My next question was answered from page 8. I am retiring as a Jet mechanic in December and was thinking I would still get some good use out of my safety wire plyers to make the twist and the article stated why not to. Saved me some headaches down the road.

RE: Why Copper wire

As a former kart racer, I still have my safety wire pliers and always use them for twisting wires. Think of them as a nice pair of needle nose vice grips, that will also twist most of your wire for you. Of course, you should stop before the wire is all the way tight, and dial the last turn or two by hand. The pair I have would be difficult to over tighten using the spiral pull anyway, so I don't really understand John's comment.

Funny the line people draw within themselves, the perception between what is more efficient using a manual or old fashioned method, versus some automated or specialized or powered tool. It varies task by task, and often counter intuitively between novice and skilled woodworkers.

RE: Why Copper wire

» Submitted by Laszlo - Wed, 7/27/16 » 1:08 PM

One reason is that steel can cut through soft woods, but the main reason is that if you leave the stitches in steel will eventually rust and copper won't.

Laszlo