Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

I'm considering using a graphite epoxy mix on the bottom of a Wood Duck nearing completion. I've already 'glassed the boat, but have not filled the weave. Two questions: (1) What's the correct ratio of graphite powder to mixed epoxy? (2) Do I fill the weave first, then apply the graphite mixture, or do I use the graphite mixture to fill the weave? Thanks. Jim

11 replies:

RE: graphite bottom coat

Hey Lazlo,

When you're filling the weave with micro ballooned thickened epoxy whats your mix ratio there?

Thanks,

Trevor Hogan

RE: graphite bottom coat

Many thanks, Laszlo. I'm also interested in the answer to Trevor's question, if you don't mind. I'm also thinking of using the Kevlar rub strips fore and aft, in conjunction with the graphite; any thoughts on that? And, by the way, your WD 12 is stunning!

Possibly related background: Nearly 15 years ago, I built a couple of Wee Lassie strippers, and used a mixture of epoxy and aluminum powder on the bottoms. It was hard to apply and impossible to sand, but it came out great and has proven to be just about indestructible over the years, despite hard use. Most people who see these boats think they are newly built. My hope is that the graphite is easier to apply and affords similar protection.

Jim

RE: graphite bottom coat

Jim,

Thanks for the kind words. Graphite/epoxy is pretty easy to apply. I just roll it on with a short nap roller (sold by CLC) and tip it out with a foam brush (also sold by CLC) Your aluminum mix bottom is probably magnitudes tougher and more appropriate than the graphite for extremely rocky areas.

Trevor,

I don't really keep track of the exact ratios for the microballoon mix. I mix it like an old cook - just put in enough. A more useful answer for you is that I usually use a couple of coats of balloon mix to fill the weave. The first coat has enough balloons to make a runny but opaque maroon mixture. It's runny enough to apply with a roller. While it looks opaque in the cup, it's somewhat see-through once it's on the boat.

The second coat coat is very stiff, stiff enough that it needs to be applied with a squeegee.

The idea is that the first coat gets down into the weave, fills it and stays there. The second coat is for filling anything that the first coat missed and also for fairing. Much of it will get sanded off. It's a bit more work to apply, but once it's cured it's very easy to sand into a fair, smooth shape.

Hope that helps,

Laszlo

RE: graphite bottom coat

Jim, I put Kevlar rub strips on my WD12, needed to. I too did the graphite bottom as Laszlo described, but found that the bow wore though on the edge very quickly [since it is so narrow]. I had the same problem on my SOF that also has graphite.

Options: on my SOF, I use some cab-o-sil thickened epoxy to create a rubstrip/bumper and covered it with epoxy & graphite, working brilliantly.

On my WD12, I went with the Kevlar since I wanted to retain the sharp edge of the bow. The SOF has a 3/4" flat on its bow. I went to my favourite supplier and asked for some kevlar scraps. From that I cut (using old scissors, kevlar kills scissors) a strip that is about 34" wide and 8" long, bow and stern. I was really worried about getting it sit down nicely on the sharp curve but it all worked out.

To apply the Kevlar, paint the area with unthickened epoxy where you want the felt to go, carefully lay the felt on the boat and stick it down. Once possitioned, saturate the fabric. I found that I had a really hard time trying to prevent runs so I came back before the epoxy had cured and cleaned up the runs with some vinegar. The felt will finish fuzzy, don't worry, once fully cured just sand it smooth (it will still have some bumps, just no fuzz), then paint with the graphite like the rest of the hull.

I think the stock rubstrips will not lie flat since they are so wide and so long, hence I went with much smaller ones, besides, when you can scavenge pieces for free :) Very happy with the results.

RE: graphite bottom coat

Follow up to Laszlo's february 12 post:

When filling the weave with the microballon mixture, how do you control the line between the bottom of the hull and sides? (assuming the bottom will be graphite and the top bright with varnish) I've read the posts about applying tape for the actual application of the graphite, but do you hold the microballoons back from varnish/graphite line to make sure none of the purple balloons end up on the sides?

Perhaps its safest to fill the weave to the actual chine and make the graphite/varnish line some distance above the chine?

Seems like the microballoon mix will end up thick relative to the unthickened epoxy filler coats on the side? Seems like the only way around that is to stop in the radius between the bottom and sides?

RE: graphite bottom coat

Wow, one from the vault.

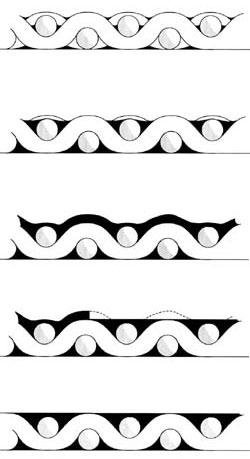

Last question first. Both the unthickened epoxy and the microballoon mix get sanded down until the weave is just filled (see picture below, borrowed from CLC Shop Tips) so they end up being the same thickness.

Controlling the line sounds worse than it actually is. Your idea of stopping the balloons before the graphite ends certainly does work. You can also just wipe off drips before they harden. Drips are also fairly easy to avoid if you apply the first runny layer in a thin coat and then mix the second layer pretty thick.

And, of course, there's always tape.

Happy New Year,

Laszlo

RE: graphite bottom coat

Question for Laszlo or any one else:

Would the graphite bottom coat work on the bottom of a heavier boat ( 18 feet, 600 lbs all up) hauled on a roller trailer? Or would the rollers rub through the graphite? Or maybe even slide on the finish and not turn.

Thanks for any info here. I've never done the graphite bottom.

RE: graphite bottom coat

What I have found works wonders is a 1/16" carbon graphite skid of about a foot long on the keel. It is spar material for RC gliders and you can buy it at most hobby shops. Saved my Chesapeake & Pygmy keels after dragging them miles over trails at Bowron lakes.

RE: graphite bottom coat

Thanks Darryl.

I think I'll end up doing something like that as there is a fiberglass batten for the bottom of the skeg.

RE: graphite bottom coat

» Submitted by Laszlo - Fri, 2/11/11 » 7:28 AM

Hey Jim,

I used 50-50 by volume on my last 2 boats and have been happy with the results. That mix works well for the kinds of bottoms I encounter around here (sand, gravel, occasional oyster shells and concrete). If you're in a very rocky area, you may want to reduce the graphite a bit and replace it with cab-o-sil.

You can use the graphite mix to fill the weave, but it'll be cheaper, easier and lighter to use a phenolic microballoon mix for weave filling, then apply the graphite/epoxy.The least desirable way to fill the weave is with unthickened epoxy. It's heavier and more expensive than filling with a mix. The only reason to do that is if you're finishing bright. If you're painting or otherwise obscuring the wood, go with a mix.

Click on the picture below to go to my Wood Duck 12 Build website's graphite/epoxy section.

Good luck,

Laszlo