Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

It's my understanding that when I buy the plans and manual for a CLC Kayak that I don't get a table of offsets. Instead, I get full size paper plans. This concerns me because paper expands and contracts so much with changes in humidity. A half inch over 12 feet is probably well within the range. Lofting from a table of offsets isn't hard. When you factor in that it removes this variable, I'd rather just loft it.

Any thoughts? Has anyone experienced problems with this?

5 replies:

RE: Full size plans vs lofting

I've built 2 boats from CLC plans- Shearwater 14 & Shearwater 16. Both were made from the plans copied onto the wood with tracing paper and the use of a french curve. I did make a 2'x16' table with grid lines to make sure all things remained square & true. The pieces to be scarfed were cut proud of the traced lines and glued/assembled on the table to make sure everything was positioned correctly. Then faired back to the lines. I was amazed how perfectly it all stitched together. The only area that needed adjustment- + & - was the keel line. I did pay particular attention to the temperature & humidity of the paper plans. I also did cut the plans down retainning the uncut straight edge of the plans to make them more manageable and used the table to reference the overall shape/squareness. And, follow Laszlo's advise

Lew

RE: Full size plans vs lofting

I've built a s&g sailing skiff from a table of offsets and two kayaks from full-size plans. I use carbon paper to transfer the plans to plywood and have not had any problems. As for paper stretching, if you keep it rolled up and indoors it's not likely to happen. And as long as it stretches evenly, it won't matter anyway. -Wes

RE: Full size plans vs lofting

Used to be, we never shipped full-sized plans. You'd have to do the layout from a diagram showing all the plywood hull parts. 15 years ago we'd experimented with full-sized plans and it didn't go well. The blue prints really would change shape a lot, although to be sure it was mainly happening at the printers, not once it was in the builder's hands.

Technically those were blue-lines, not blue prints. Blue print/blue line creation involves getting the paper wet (I think the chemical is ferro-gallate), and at the moment of printing you'd get nasty errors on the very long pieces of paper required for kayak parts. We gave up.

But that was 15 years ago, and the technology has moved on. Now CLC's plans are laser-printed, and there is little or no distortion when the prints are made. Since 2005 or so, all new CLC plan sets come in the form of full-sized patterns. Eventually all of the older plan sets will be revised to include full-sized patterns for every part. (That's hundreds of hours of CAD work, so it won't happen overnight.)

A note on the use of the word "lofting." A lot of people---more every year---ask if CLC boats require lofting. "No, absolutely not," I say. "On our boats without full-sized plans, you'll just need to transfer diagrams from the plans to the plywood, bend some battens, and start cutting."

Blank stare. "Isn't that lofting?" No. Lofting means something extremely specific to professional boatbuilders. It's an esoteric process of converting a "table of offsets" or coordinates into a full-sized plan, elevation, and body view of a hull shape (often along with construction details, for the making of patterns).

Scaling up a diagram for the shapes of plywood parts isn't lofting, it's "layout." The same thing as a house carpenter marking off where the studs go. The carpenter definitely isn't "lofting"!

Lots of boats for home builders out there that require lofting, the real deal, but not in our stable of craft.

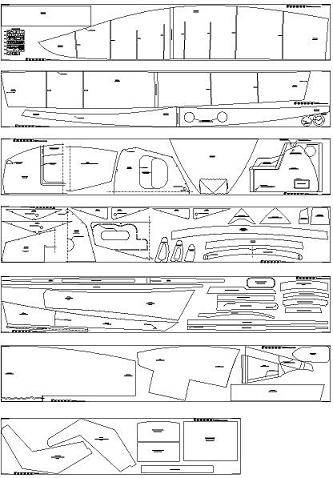

PocketShip's full-sized plans:

RE: Full size plans vs lofting

I built a Wood Duck 12 hybrid from full sized plans without any problems at all.

Now I am building a Guillemot and a Petrel using only the lofting offset charts in Nick Schades books. It took me about 8 or 10 hours to loft the parts for each kayak. I could have just bought the prints and be done with it all, But it gave me a great cense of accomplishment to do it all from scratch.

If you are on a tight budget, it saves you the cost of a set of plans. Money that can go to the cost of epoxy and wood.

Lou

RE: Full size plans vs lofting

» Submitted by Laszlo - Fri, 2/4/11 » 7:23 AM

The plans I've bought have not been meant just for tracing. The had scaled dimensioned drawings. A few bits were at a 1:1 scale and could have been traced, but those were parts were the tolerances were pretty high (1/4 inch or more).

For many of the boats the tolerances are such that paper stretching is not all that important. The accuracies are dominated by the ability of the wood to twist and bend, which varies from one sheet to another, wood being a natural product and all that. (There's probably more variation in the fairing battens than in the paper.) The dimensions tend to be a guide, sort of like recipes in a cookbook.

The important thing is not the actual length of the boat, but rather the symmetry and fairness. If you're really worried, lay out the critical parts on the same day and they'll match.

Laszlo