By John C. Harris

June 2013

Our 22'6" rowing-sailing pocket cruiser has hit the water and seems to be a great success. Read about the origins of the project here. Scroll down for the latest photos.

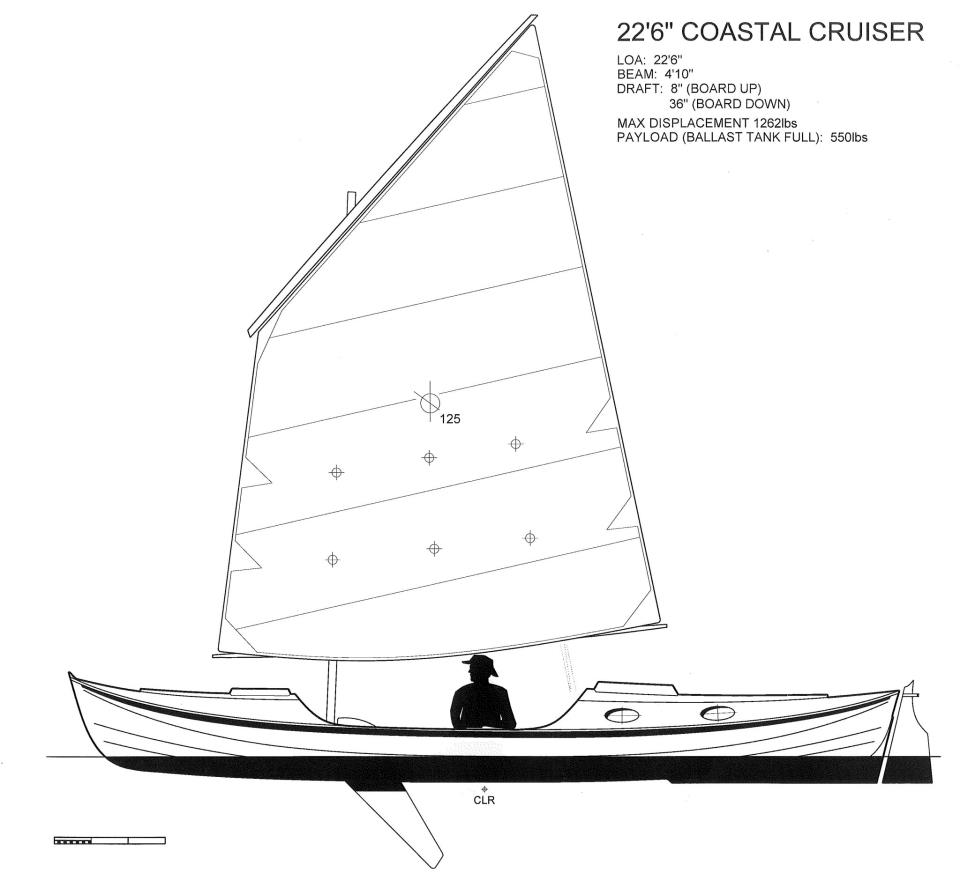

The design was commissioned by an individual with three firm requirements for a coastal cruiser: the boat must sail, offer sliding seat rowing as auxiliary power, and have sleeping accommodations beneath a hard deck. It was a very unusual design brief, and at length this was my best effort at incorporating those features.

While apprehensive that the boat could do everything well, I think the result has fetching lines and real possibilities for a singlehander. Mike O'Brien was sufficiently taken with the boat to put it on the cover of the current issue of Boat Design Quarterly.

There has been lots of interest in kits or plans. Since we cut all of the boat's parts on our CNC machine, a "kit" exists, more or less---we load plywood on the CNC machine and press "go." The parts fit together well, and some advanced builders would be content with that. But most people define a kit as more than simply a giant jigsaw puzzle of okoume plywood. A kit is ALL the stuff...epoxy, fiberglass, solid timber, hardware, and above all, a comprehensive step-by-step instruction manual. That takes a lot of time to put together.

A kit comprising the CNC-cut plywood parts, solid timber ready to be milled, epoxy, and fiberglass will cost about $4500. Spars, sail, oars, sliding seat rig, hardware, paint, and varnish not included.

I took enough photos during construction to piece together a basic instruction manual. That's likely a few months off, however. We are currently finishing up a set of plans. Either in kit or plans form, this isn't a beginner's project, but it might be just the thing for small boat nuts with a few projects under their belt.

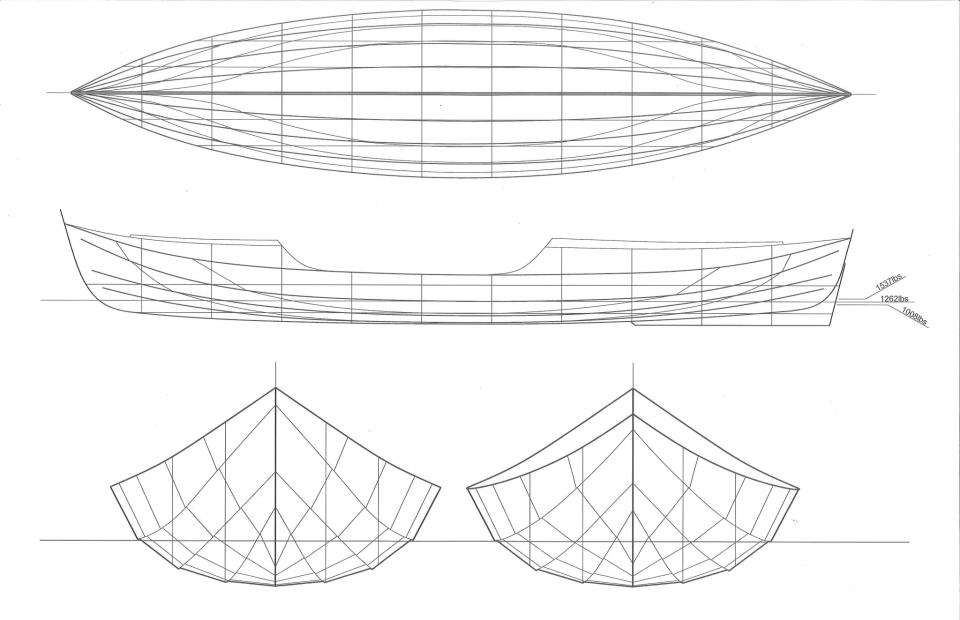

("Wait!" I hear you say. "Didn't you have to draw the plans FIRST, before you built the boat? And thus there is no need for dithering or delay in offering the plans for sale?" Well, no, not exactly. Scroll down for all the drawings that exist in the world. They were sufficient for the professionals in our shop to fabricate and locate parts in the assembly, and of course there is digital data for CNC cutting of the various components. But "boat plans" are a graphic design exercise, where dimensions and explanations are added, diagrams are scaled to fit ARCH-D sized paper, tricky bits are amplified and rendered, and we try to anticipate every possible question a builder might have. Yes, these days the work is done in computers, but none of it is automated in any way. It's still a laborious procedure that takes just as long as it did in 1950.)

The owner tries out the cuddy. The "enclosure" ("cabin" would be stretching the term) is eight feet long, four feet wide, and two feet high, about like a large one-man tent. It isn't big enough to really set up house, but for keeping your gear dry and sleeping out of the rain, it's great. A ventilation scheme works when the hatch is shut, and won't flood the boat even when inverted.

To have any hope of performance under oars, the lines needed to be pretty slack. The hull is a fairly pious replica of traditional Norwegian faerings, boats famous for excellent rowing and sailing qualities.

An optional sloop rig, with a mast in a tabernacle. This would yield a very sporty sailboat indeed.

Pretty much the final configuration.

The lug rig that was chosen, for its ease of handling and low center of effort.

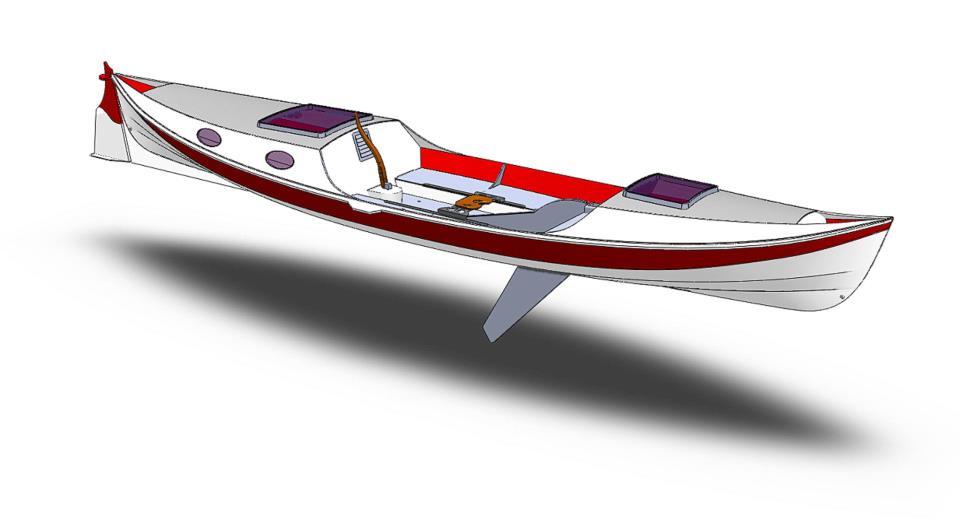

Beautiful CAD rendering by Jay Hockenberry. The tiller folds up to clear the cockpit for rowing, locking the rudder on the centerline in the process. Rudder and tiller are connected by cables.

Laminating the rails.

Ready for decks.

Decks on and fiberglassed. Bill actually managed to lever himself into the forward compartment to clean up the epoxy. Note light and fan. The forward compartment is just for storage.

June 12th, 2013: Last coat of epoxy, and it's all over but the sanding...

Last minute work at the shop. A good view of the sliding seat, which lifts out and stows in seconds to clear the cockpit for sailing.

Launch!

Heading out of Spa Creek for the first sail. An easily-driven hull...

Sat dead level on her lines. Always a relief to the designer!

The designer gives her a go under oars. I've been keeping expectations modest about rowing performance, but it really glides along nicely. Felt like I could row it all day, at least in smooth conditions.

Sorting out the lazy jacks.

A good ghoster, as you can imagine, with that narrow waterline.

Once out on the Severn River, we had about 10 knots of breeze to play with. The boat is fast, weatherly, and comfortable. You need to mind the mainsheet, of course, but with two aboard it was easy to keep flat. With only one person aboard, you'll need the 270lbs of water ballast beneath the cockpit sole for stability.

From a recent trip to Maine:

return to section:

return to section: