Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Laser Friendly Plywood for Boat Building

Hello,

Backstory:

I own and operate a 100W CO2 laser and I am in the process of designing my first boat. I am on the hunt for a plywood that I can laser cut.

Boat to be designed:

It will be small (~6' long).

It will be a stitch-n-glue construction.

It will be glassed (6oz inside and out) and heavily epoxied.

It will be a kayak-esk design, which I am hoping to catch some small waves with and take in rough water.

The problems with laser cutting some plywoods:

- Some plywoods actually have metal-flakes in their glue, which spark and cut poorly on a CO2 Laser.

- Some plywoods use formaldehyde-based glues, which smell absolutely nasty when laser-cut and are not good to breath.

My limited understanding of Marine-Grade plywoods:

- The biggest benefits are:

1. Waterproof glues (that all contain formaldehyde?)

2. No inner voids

Comments:

C1. I tested very inexpensive 1/8" Luan (mahogany) ply by dunking it in water for a week, and the layers did not de-laminate even though it does not seem to be a "water-proof" glue. This is leading me to believe that the water-proof-ness of marine-grade ply is not necessary for my application.

C2. If I were to source a ply made with non-waterproof glue, but still had no-voids, it seems Baltic Birch (cabinet grade) is my best option. But whether or not I would go that route depends on whether or not the small and seldom voids found in inexpensive Luan ply is really a problem.

Questions:

Q1. If I am going to be heavily glassing / epoxying my boat, then do I really need my plywood to be made with water-proof glues?

Q2. For that matter, do I really need my plywood to be totally void-free?

Q3. Is there a Marine Grade plywood that is commonly laser-cut?

Q4. What would be the next best laser-friendly plywood?

9 replies:

RE: Laser Friendly Plywood for Boat Building

Thanks for the helpful info Laszio.

Regarding: Luan vs Marine Grade plywood: I agree Luan is far from ideal, and I plan on avoiding it. That being said, if I can find an interior-grade wood like Baltic Birch that has no voids, equal ply thickness, same-material inner-plys, but lacks the "water-proof" glue, then I see no reason to avoid that if it passes a water soak test.

Regarding Boat Size: I chose 6' because I have a design goal of keeping this thing as small as possible. I've seen 8' versions done with success, so figured I could get away with 6'. Even CLC has a 6' boat, but it is about 4' wide I believe. I'm shooting for 2' wide.

Regarding Laser-Cutting: I'm designing the boat in CAD to begin with, so transitioning to laser/cnc wouldn't be much more work. I also like the idea of being able to quickly replicate it to send to friends. Perhaps my best solution would be to laser templates, that would be layed out on a single ply sheet and then used to simply mark before cutting. (with a saw as per your suggestion).

RE: Laser Friendly Plywood for Boat Building

Well...

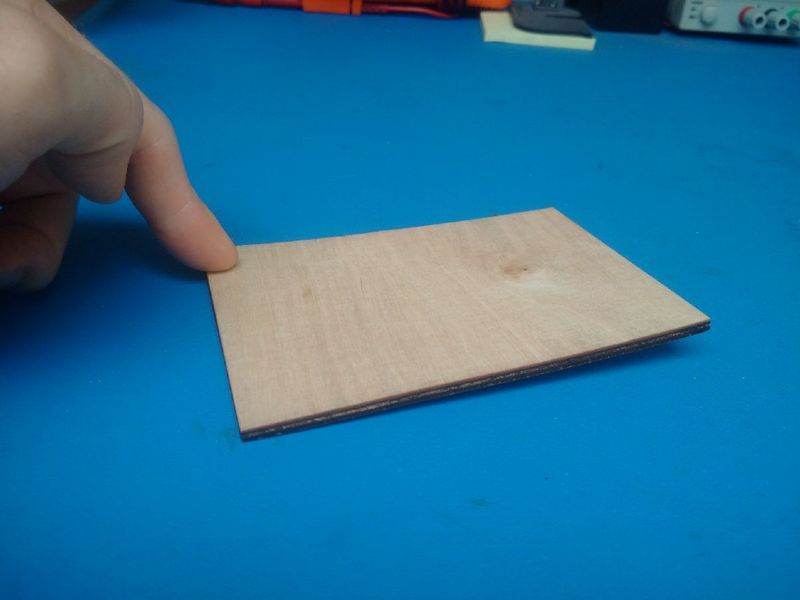

I found some 5/32" (4mm) Baltic Birch (Exterior-Grade) plywood. it has no voids, 3 equal sized Plys, and waterproof glue.

It is reasonably flat (critical for laser cutting) and it doesn't spark like that Marine-grade stuff (that I presume had metal flakes in the glue).

When laser-cutting, it doesn't smell as nice as the Interior-grade stuff, but ity's not nearly as rank as the Marine-Grade stuff that I had tried cutting previously. I've got it all hooded, filtered, and vented outside as well, so that should keep me from dying.

- $45 per 4'x8' sheet

- no voids

- waterproof

- equal ply thickness...

The only thing I'm left wondering:

What specific advantages would Marine-Grade offer over this?

RE: Laser Friendly Plywood for Boat Building

Depends on the marine plywood. Okoume is lighter and more flexible, so if you're making something that needs radical bending or that needs to be light, it would be better to use okoume.

Laszlo

RE: Laser Friendly Plywood for Boat Building

Thanks Laszlo, good to know.

Looking forward to reaching out to you in the distant future when I am done with this project. Hopefully you will get a kick out of it, and if I share video footage of me tipping over on the first turn you can totally say "I told you so". lol!

;-)

RE: Laser Friendly Plywood for Boat Building

Loads more on marine plywood in the current issue of WoodenBoat. They've posted the article online.

As for laser-cutting plywood, CLC got a 60-watt laser cutter over the winter and we've been playing with it. We got it to cut very thin modeling plywood (for model boats, of course). It seems to max out around 6mm in thickness, just because of the amount of charring. That could have to do with the size of our laser; I'm no expert.

RE: Laser Friendly Plywood for Boat Building

A 6' boat that is only 2' wide will sit deeper in the water than I'd like for a kayak (at least 4"). It will also be quite tippy. I've got a 10' skin-on-frame kayak that's 28" wide. That's as small as I'd want to go -- and I weigh less than 150.

RE: Laser Friendly Plywood for Boat Building

How about one for each foot? :-)

A bit more seriously, sounds like the basis for a trimaran sit-on-top.

Laszlo

RE: Laser Friendly Plywood for Boat Building

So... the 5/32" (4mm) Baltic Birch (Exterior-Grade) plywood that I found passes the boil-test and the 7-day water-soak test without any signs of delamination of plys.

However, the wood piece does show more warpage than the 1/8" Luan that I tested.

Question: Is warp after the boil / water-soak test normal?

-Josh!

RE: Laser Friendly Plywood for Boat Building

» Submitted by Laszlo - Sun, 4/30/17 » 8:23 AM

Josh,

So many questions in one post, but I'll give them a go. First, here's a link to an article addressing many of your marine vs. non-marine questions. The condensed answer is that marine plywood wins overall when you consider the cost of fillers, epoxy, glass, sandpaper, etc. that you need to make up for non-marine plywood's flaws (not to mention the labor).

If you're just going to be using the plywood for a composite core, the skins will have to be stiff enough to carry the entire tensile load. That means a much heavier build, more epoxy and more glass (more money and time). And you still can't have any voids because they act as stress concentrators. As the panel flexes (and boats are always flexing), the wood over the void will fail from fatigue and start the delamination process.

A 6-ft boat is a very small one. CLC's surf kayak is 8 1/2 long and my feet don't fit into it. At 6 feet you're going to have some serious capacity and stability problems. If you make the boat deep enough to hold an average-sized person at 6-ft, you'll mess up the proportions and the handling will suck.

I'm guessing that the 6-ft limit is cause by the laser cutter bed. Consider a larger boat instead and join the 6-ft planks using butt blocks, scarph joints or, since you have a laser cutter, puzzle joints.

Finally, FWIW, I think that your laser cutter may be hindering you instead of helping. For a one-off boat, it's a lot faster to cut the wood by hand, even with an unpowered saw, than it is to put together a digital model, verify it and then cut it with the laser cutter, especially since saws have no length limitations. It's not until you get into mass production that automation begins to help you out. A filtered hood, BTW, will take care of the toxic smoke problem and allow you to use panels manufactured with resorcinol glues.

Good luck,

Laszlo