Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

Questions About the Skerry Rudder (2nd attempt)

Q1: So I'm committing the hardware in place for the rudder/tiller/blade assembly before painting and varnishing, and am wondering what others have done for the deployment line for the rudder. The line comes out of the rudder much higher than the manual illustrates, so there is no place for the cam cleat as illustrated. Like this:

And a close-up of where it exits the rudder, right under the yoke - so close, that I drilled/filled a hole for it to escape, figuring the top of the yoke may be the best place for the cleat, like this, but now I'm having doubts:

An alternative is to have the line come up from the bottom, but there's not much purchase in the corner of the yoke for a screw:

Anyway, how have you handled this?

Q2: I've read others talk about using a bungie to keep the rudder up and out fo the way when not in use. Does anyone have a photo to illustrate how to rig that up?

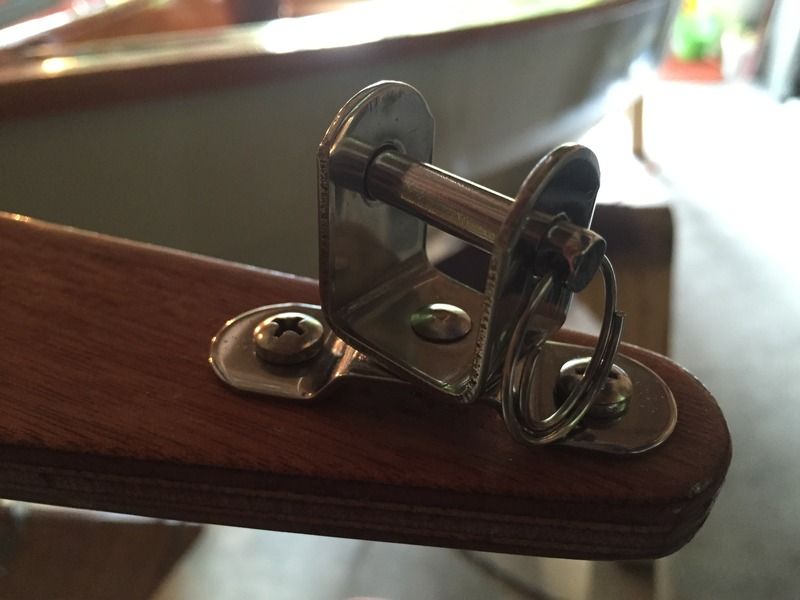

Q3: Not really a question, but a thank you to Moonchaser who suggested one of the coolest $10 finds out there from Duckworks for the tiller. Thanks!:

Matt

5 replies:

RE: Questions About the Skerry Rudder (2nd attempt)

I did something similar with my Skerry rudder. It looks like there was a design change at some point relative to what's in the manual. I used the jam cleat on top of the arm, but set straight fore/aft. You'll note the filled holes where I put it too close to the rudder head fillets. I through bolted it for strength, but was too close to the fillet for a flat surface for the washer & nut.

I also put a plastic fairlead on the trailing edge of the tiller arm to give the line some guidance.

On this one, I bedded the screws in epoxy, since I was going into the edge of the plywood.

I've only had a couple of outings with it so far, but it works well enough to yank down the rudder blade without too much effort. The trick though is that when you lift the line out of the clam cleat, it tends to drop back on top of the jaws and then self-tightens back into the cleat when you really want it loose to let the blade swing up as you approach the shore. For now I am looping the line around the rudder head to keep it from falling back into the jaws:

RE: Questions About the Skerry Rudder (2nd attempt)

My rudder line is unsecured. I have a piece of wood for a handle on the end of the line and after setting off I pull the line to lower the rudder blade and just let the handle and line hang in the stern of the boat. The rudder has never swung up whilst in use ( maybe I made it too good a fit. :) ). If it did, I'd yank it back down again. I'm not so sure I want the line held tight, the rudder is designed to swing up for beaching etc and if the line is held tight . . .

RE: Questions About the Skerry Rudder (2nd attempt)

Yambo, yes, agreed, in that, what good is a kick up rudder, if it's not going to kick up, when you really need it to. Perhaps a solution is to use a stretch cord, instead of fixed line, for the pull-rudder-down line. That way the line keeps the rudder down, and if the rudder hits something, it should still have some give to it, even though the rudder line is secure.

Has anyone employed a pull-rudder-up line, for use when backing the skerry down a concrete boat ramp, with the rudder and tiller already in place?

RE: Questions About the Skerry Rudder (2nd attempt)

https://www.christinedemerchant.com/rudder.html

scroll down on that page

Ruud

RE: Questions About the Skerry Rudder (2nd attempt)

» Submitted by Laszlo - Sat, 5/28/16 » 6:20 AM

Nice work on the boat.

Looking at this:

I'm thinking that it would bind unless it's led through blocks.

Have fun,

Laszlo