Builders' Forum |

|

| ↓ Scroll to Last Comment ↓ | Forum Guidelines | Builders' Forum | |

I own a decorative concrete company and we install a lot of epoxy floors, along with many other high performance coatings. We use uv stable water clear industrial epoxies in several varieties, so I have been wondering why everyone uses epoxies that require varnish to provide uv protection?

Dave

14 replies:

RE: Nobody uses uv stable epoxy?

Thanks Laszlo, thats the explanation I was looking for. Yes, I know that the epoxies I use probably wouldn't work well for boats, however I might try some scrap's to test. I was mainly wondering why the uv additives werent being used in the MAS and West System epoxies. Using varnish is not a problem, just another step and added time, but I just set myself up a hvlp spray booth to speed that up for my current projects.

While I was looking at the epoxies, I also looked at some of my other supplies. I might have to play with some of my Reflector additives for some decorative applcations, especially on my Kaholo projects.

Heres an example..

RE: Nobody uses uv stable epoxy?

Ok , An old saying" Ya cant intoduce a gun into the script and not fire it, I know this is a boat forum but that is a dam impressive floor , so I do think ya going to have to elaborate a bit, Whats under the epoxy and how in the hell did you get that to look so shiny and smooth,,,,,,,,,,

Cheers Locky,

RE: Nobody uses uv stable epoxy?

Hey Locky,

This is a standard Reflector epoxy system. The concrete is prepped and a moisture barrier is applied. The Reflector matalic powders are mixed with the epoxy and applied, then allowed to self level which together with the application meathod, gives the "movement" to the Reflector and the smooth finish. Then in this application a polyaspartic top coat is applied. Fast and easy, in and out in 3 days and get my check!

RE: Nobody uses uv stable epoxy?

Thanx for the reply, I gota say if thats the way you do your floors I cant wait to see how the kaholo turns out, I might add its good to see something new and different, Ive never seen that before, thank you for shareing and dont worry I deffinatly wont be trying it, I had enough trouble just trying to get my marine varnish right,

cheers Locky

RE: Nobody uses uv stable epoxy?

I'd sure be willing to pay more for a UV stable epoxy. Just knowing its not going to be sun damaged so quickly is worth alot, as well as taking into account the cost of good varnish, the time and angst of applications, and perhaps most of all- sanding and sanding between coats.

Hickory

RE: Nobody uses uv stable epoxy?

Claims of UV-resistant epoxy seem to come and go with the seasons. In 25 years of building boats I have yet to encounter an epoxy with the structural and handling properties we need for boatbuilding that is also "UV resistant."

Notwithstanding the claims of some epoxy makers, I'm not sure it can be done. Flooring epoxies always seem to be used indoors, where there is simply a lot less harsh UV light. Nor do flooring epoxies stay clear for very long---big polishing machines are deployed at intervals to buff the oxidized surface. In addition, I haven't come across a flooring epoxy that was really suitable for wetting out fiberglass, or that had the proven tensile strength we need to hold boats together.

I had an epoxy chemist explain to me, in language adapted to my limited grasp of chemistry, why UV resistant epoxies don't really work in a marine setting. I created some quickie diagrams to accompany his description, and keep in mind that this all very simplified.

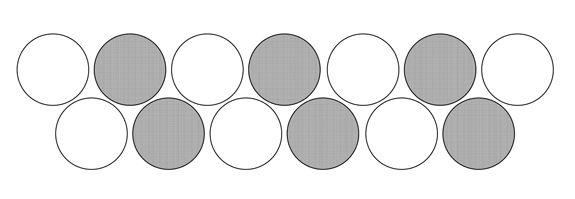

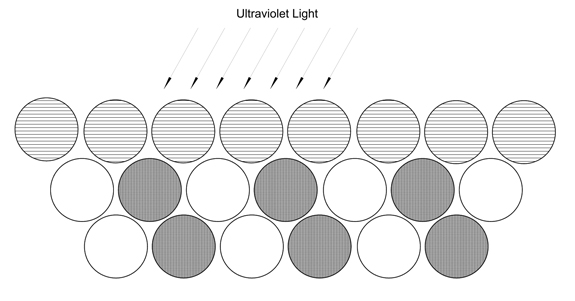

"Think of epoxy as resin gumballs and hardener gumballs. You mix them up and coat the deck of your boat with the mix. The resulting surface is a mixture of resin and hardener gumballs."

Since the (chemically bound) resin and hardener gumballs aren't resistant to the sun's rays, the epoxy on your deck will eventually break down at the microscopic level, and grow increasingly cloudy.

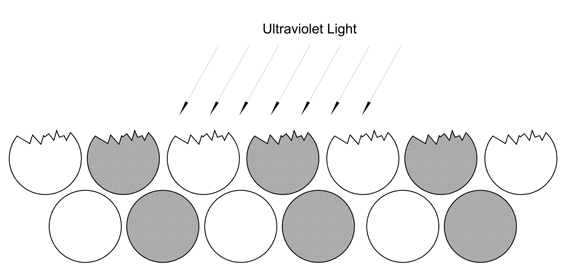

Okay, so let's add UV-resistant gumballs to the mix! Save all of this tiresome varnishing work. We mix up resin, hardener, and UV-resistant gumballs and roll it onto our boat.

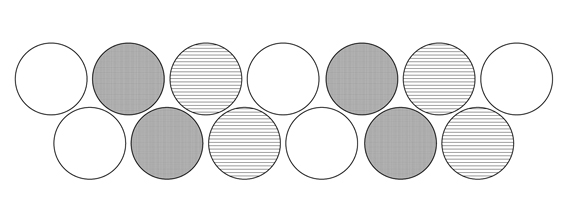

Now the surface consists of resin, hardener, and UV-resistant gumballs. This is an improvement, but the epoxy continues to break down, as shown:

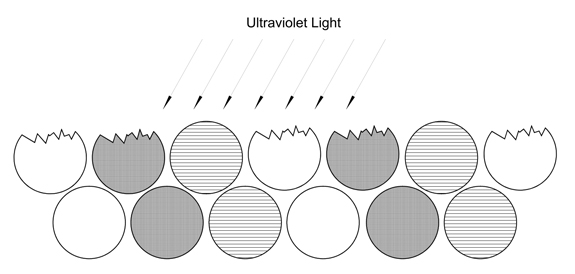

So, what boatbuilders prefer to do is to apply a coating of ordinary epoxy for strength and waterproofness. But over the top of the cured epoxy we roll on a thick coating of UV-resistant gumballs in the form of paint or varnish. It's not perfect---even these marine coatings that are optimized for UV resistance don't hold up forever beneath the sun's relentless rays.

RE: Nobody uses uv stable epoxy?

John, Thanks for the better explanation. You are correct in that in most high uv exposure applications we prefer to apply an Aliphatic Urethane or a high solids, two component polyaspartic ester coating to protect the epoxy from uv and to add extra abrasion resistance.

The diagrams you showed above explains how , in the coatings industry we use uv stable or resistant epoxies. We apply the epoxy in thin coats which gives a better distribution of uv resistant material over the previous coats. Also, in most exterior epoxy situations we are not applying clear epoxy, so slight ambering is not usually noticed if it does occur. And yes, over time they do need maintenance, thankfully for those of us who make their living applying them!

Anyway, thanks for responding. I am using the MAS epoxy I bought from you, but was just wondering why their were no uv resistant options. Now I know. And believe me, it is a lot easier to achieve a flawless smooth coating with varnish than with epoxy is a situation where the epoxy can't self level! To achieve that smoothness I am usually burning through epoxy at 50-60 square feet per gallon at $70+ a gallon.

Any way, Ive got to get back to working on both Kaholo decks so I can finish these up. I already have the Wood Ducking and Nymph kits waiting for me to clear off some space.

RE: Nobody uses uv stable epoxy?

Built a Kaholo for my daughter, no warnish yet - just "had" to go in the water - and after a year it still looks fine with WEST system resin and 207 hardener. Board is inside when not in use. Test number two, a catamaran I built daughter more than two years ago = WEST with 207 plus a couple coats of spar varnish. Cat spends most of her life outside and the varnish needs a redo, and the epoxy coat is beginning to pale.

Bottom line - for stuff that sits outside WESAT w/207 and multiple coats of spar varnish is best - not two skinny coats of varnish.

RE: Nobody uses uv stable epoxy?

A few years ago some of the surf industry gurus came up with a uv friendly epoxy called Resin Research. They claimed it would do great and wonderful things and never delaminate in the sun. At the time I was building the BETA Sea Island Sport and decided to give this stuff a go. It was a three part system, resin, hardener and Additive F. You found out the hard way if you didn't use the Additive F the next coat wouldn't bond to the first. Anyway I finally got the boat done. There were two main problems. First, the stuff didn't wet out the glass like MAS or System 3 so the sapele deck is a bit muted. I also did some leaf onlays which looked okay but also a bit muted. And secondly, and worst of all, after being in the sun for a few years the stuff has entirely gone south and I am about to have to strip the entire boat and re-glass.

So I have learned a valuable lesson and will stick with the tried and true systems like MAS (my personal favorite), System Three, etc. Varnishing isn't so bad when you look at having to strip and re-glass an entire boat.

George K

RE: Nobody uses uv stable epoxy?

I have not used the new Westsystems 207 epoxy so I am not sure how clear it stays. RR resin is always being updated and my friend swear by it and don't use the additive F. I built my Kaholo 15 months ago and used Green Room epoxy resin . It was formulated for epoxy surfboards by Eversoul Resin Industries. It is clearer than clear and is very UV resistant !! I did all my glassing with it and the sprayed Automotive clear coat over the top ! I paddle my Kaholo 5 miles 6 days a week and it lives on the top of my truck which is parked under a mango tree during the day and in my shop at night. After 16 months there is no clouding ,fading, yellowing. This resin is the most amazing resin I have ever used !!! But it goes of fast allthough they allso have a slow version !! The problem is there are only 2 or 3 destributors , East coast and one on the West coast. So the resin has to be shipped by UPS. I think it is about as close to perfect as epoxy resin can get and I am sure that the automotive clear coat helps a lot.

http://www2.swaylocks.com/forums/wood_ogre-builds-14-ft-koa-kaholo-kook-box

here is a link to my building thread I think you will find it very interesting !!

RE: Nobody uses uv stable epoxy?

How about just putting a UV cover over the exposed surfaces it when it is out of the water. Check out Topless Boardbags. You can find them on the internet at www.uvboardbags.com.

RE: Nobody uses uv stable epoxy?

What an intelligent and enlightening thread. And that floor looks dynamite. I used to strip/wax floors do thsts my (arduous) connection.

Good read Dave, thanks.

Pete

RE: Nobody uses uv stable epoxy?

» Submitted by Laszlo - Tue, 12/4/12 » 6:24 AM

Dave,

I don't know what you use in your business, but I'm guessing that it's been optimized for floors and that it doesn't have all the qualities that boats need.

Floor coatings mainly have to stand up to people stepping on them, things being put on them and have to resist scratching. That's strength in compression and abrasion resistance. For boats the epoxy also needs to be compatible with fiberglass (high viscosity for wetting out, good adhesion to glass and high modulus) and it has to bond well to wood for use as an adhesive, as well as a coating.

I know that there are some epoxies that do all that and are UV stable, but those are more expensive. For hobby work the free labor and low volume justify a cheaper epoxy and a can of varnish, especially since the final finish is easier to control with varnish when using hobbyist equipment (no molds, vacuum bags, etc.).

Laszlo